Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

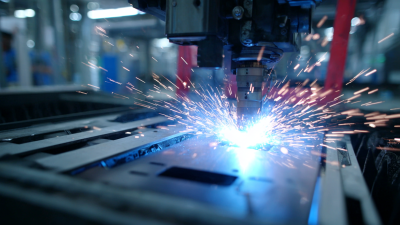

As the manufacturing landscape evolves, the importance of efficient and innovative solutions has never been more crucial. The field of Robot Welding Consumables is experiencing a notable transformation, driven by advancements in technology and increased demand for quality and efficiency. According to the International Institute of Welding, the global market for welding consumables is expected to exceed $25 billion by 2025, highlighting the significance of this sector in the overall manufacturing industry.

In this context, industry expert Dr. Emily Carter emphasizes the role of Robot Welding Consumables in enhancing productivity: “The right consumables not only improve the speed and quality of welding but also play a pivotal role in minimizing operational costs.” As robotic automation continues to penetrate various manufacturing processes, understanding the trends and innovations in welding consumables becomes essential for companies aiming to optimize their production methods and stay competitive in the market.

The forthcoming analysis of the "2025 Top 10 Robot Welding Consumables" sheds light on cutting-edge materials and technologies that are setting benchmarks in industry efficiency. By focusing on these top consumables, manufacturers can significantly drive their operational effectiveness, thus reinforcing the notion that selecting the right Robot Welding Consumables is a strategic imperative for success in the modern manufacturing ecosystem.

As we approach 2025, the landscape of robot welding consumables is set to evolve dramatically, driven by emerging trends that prioritize efficiency and innovation. Manufacturers are increasingly focusing on developing consumables that not only improve performance but also enhance sustainability. With a surge in demand for eco-friendly solutions, the introduction of biodegradable fluxes and recyclable materials is becoming a highlight in the market. This shift reflects a broader trend toward responsible manufacturing practices, which is crucial as industries respond to environmental concerns.

Tips for companies looking to stay ahead in this evolving market include investing in research and development to adapt to these new trends. Collaborating with technology providers can also yield component developments that integrate cutting-edge welding techniques, ensuring competitiveness. Furthermore, attending industry events such as FABTECH provides invaluable insights into innovative approaches and technologies, which can help businesses align their strategies with market demands.

The anticipated growth in the global welding market signifies the importance of these advancements. By focusing on innovation in consumables, businesses can enhance production efficiency and meet the evolving needs of clients, ultimately driving growth in an increasingly competitive landscape.

In the pursuit of enhanced efficiency and innovation in the welding industry, the choice of high-performance welding electrodes plays a crucial role. These consumables are not just basic tools; they are engineered to provide superior performance in various applications. A report from the International Institute of Welding highlights that using high-quality welding electrodes can increase productivity by up to 30%, due to their ability to deliver smoother arcs and improved bead appearance.

High-performance electrodes are characterized by their unique compositions, which often include alloying elements that enhance arc stability and reduce spatter. Brands like ESAB and Lincoln Electric are at the forefront, offering electrodes that provide excellent mechanical properties, even under challenging conditions. Efficient welding processes not only rely on the type of electrode but also on their compatibility with various welding machines, as indicated by data from the Welding Equipment Manufacturers Association, which found that optimized electrode selection can lead to a reduction in overall production costs by up to 15%.

Tip: When selecting welding electrodes, always consider the specific requirements of your project, such as material type and joint configuration, to maximize efficiency and minimize waste. Additionally, ensure that you are using electrodes that are suited to your welding power source to achieve the best results.

The landscape of industrial welding is undergoing a significant transformation, primarily driven by the introduction of innovative flux-cored wires. These consumables are at the forefront of improving welding efficiency, with studies indicating that they can enhance deposition rates by up to 50% compared to traditional solid wires. A recent market analysis by Smithers Pira highlighted that the global welding consumables market is projected to reach $16 billion by 2025, with flux-cored wires accounting for a substantial share due to their ability to facilitate faster and more efficient welding processes.

Furthermore, the unique properties of advanced flux-cored wires, such as their ability to perform well in various positions and conditions, have made them increasingly popular across various industries, including construction and manufacturing. According to a Welding Journal report, these wires not only reduce the need for additional equipment by eliminating the requirement for shielding gas but also allow for seamless welding of thicker materials. This efficiency gain contributes to a notable decrease in overall production costs, making them a preferred choice among manufacturers aiming to enhance productivity and innovation in welding applications.

Sustainable practices in the production of welding consumables are becoming increasingly critical as the industry strives for efficiency and innovation. Manufacturers are now focusing on eco-friendly materials and processes to reduce waste and lower their carbon footprints. This shift not only supports environmental goals but also aligns with the growing demand for responsible production methods in the market. By incorporating sustainable practices, companies can enhance their brand image and appeal to environmentally conscious customers.

Tips for Implementing Sustainable Practices:

Consider utilizing recycled materials in the production of welding consumables, which not only decreases waste but can also reduce costs. Additionally, investing in energy-efficient equipment can significantly lower energy consumption during the manufacturing process. Regular training for employees on sustainable practices will encourage a culture of environmental responsibility within the organization.

The trend toward sustainability is also driven by technological advancements, which allow for improved production techniques that minimize resource use. As the welding industry evolves, those who prioritize sustainable practices will likely lead the way, setting new standards for efficiency and innovation in the market.

The welding industry is undergoing a significant transformation as automation increasingly incorporates smart consumables designed to boost efficiency and precision. According to a recent report by MarketsandMarkets, the global welding consumables market is projected to reach USD 22 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.5%. Smart consumables, which integrate advanced technologies such as sensors and data analytics, play a pivotal role in this growth by enabling real-time monitoring and adjustment during the welding process. This innovation not only enhances the quality of welds but also minimizes waste and operational costs.

Moreover, the adoption of smart consumables is expected to elevate productivity levels within the industry. A study by Research and Markets estimates that the use of intelligent welding systems can improve productivity by up to 30%. These consumables facilitate better tracking of usage patterns and performance metrics, allowing manufacturers to optimize their welding processes and reduce downtime. As the industry gears up for the challenges of the future, investing in smart consumables not only future-proofs operations but also helps companies maintain a competitive edge in an increasingly automated environment.

| Rank | Consumable Type | Material | Efficiency Boost (%) | Innovation Highlights |

|---|---|---|---|---|

| 1 | Welding Electrodes | Mild Steel | 15 | Enhanced arc stability |

| 2 | Welding Wires | Stainless Steel | 20 | Lower spatter and cleaner finish |

| 3 | Flux Cored Wires | Carbon Steel | 18 | Self-shielding properties |

| 4 | Tungsten Electrodes | Tungsten | 22 | Improved arc performance |

| 5 | Gas Nozzles | Copper | 10 | Enhanced cooling efficiency |

| 6 | Contact Tips | Copper | 12 | Improved conductivity |

| 7 | Anti-Spatter Solutions | Chemical | 25 | Reduces post-weld cleanup |

| 8 | Welding Flux | Special Blend | 30 | Improves weld penetration |

| 9 | Protective Coatings | Ceramic | 17 | Increases durability |

| 10 | Welding Fume Extractors | Mechanical | 28 | Improves workplace safety |