Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Aerospace welding is a critical process in the aviation industry. According to Dr. Emily Hughes, a leading expert in Aerospace Welding, "The quality of a weld can determine the safety of an entire aircraft." This statement underscores the importance of mastering welding techniques in aerospace applications.

Understanding the various welding approaches is essential for engineers. Different aircraft structures require specific methods to ensure durability and performance. Techniques such as TIG, MIG, and laser welding each have unique advantages. Therefore, choosing the right technique can be challenging.

Despite advancements, challenges still exist in Aerospace Welding. Certain methods may not be suitable for all materials. Further research is required to refine techniques. The industry must address these imperfections to enhance safety and reliability.

Aerospace welding is a critical process in aircraft manufacturing. Advanced methods ensure structural integrity and durability. Key techniques include TIG, MIG, laser welding, electron beam welding, and solid-state welding. Each method has its advantages, making them suitable for different materials and applications.

TIG welding, for instance, provides excellent control over heat input. It is ideal for aluminum and titanium, which are widely used in aerospace. MIG welding, on the other hand, is faster and can handle thicker materials. For high precision tasks, laser welding shines due to its focused energy and minimal heat-affected zone.

**Tip**: Always evaluate the material type before choosing a welding technique. Each material responds differently.

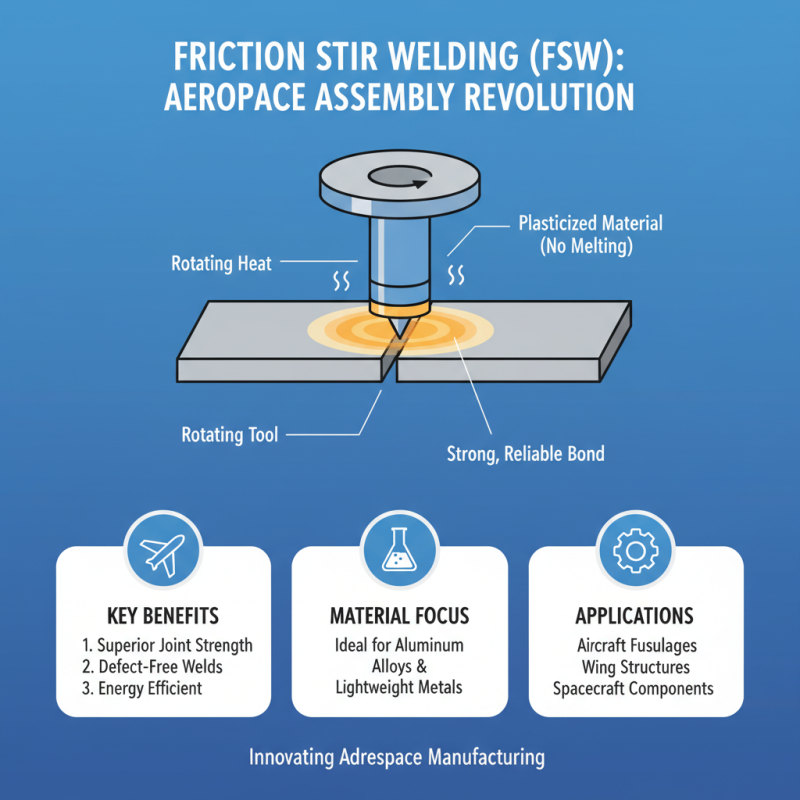

Solid-state welding, like friction stir welding, eliminates melting. This technique enhances material properties, making it a popular choice in aerospace sectors. Meanwhile, electron beam welding offers deep penetration and minimal distortion. These qualities are crucial for critical aircraft components.

**Tip**: Stay updated on industry trends and technologies. New methods are being developed constantly.

Understanding the right technique is essential. Each choice impacts the final product's performance and safety. Reflecting on past projects can provide insights into what works and what doesn't. Embrace learning to enhance your welding practices.

Arc welding stands out as a critical technique in aerospace manufacturing. This method involves melting the base metal and adding filler material for strong joints. It’s essential for components like fuselages and wings. The precision required can be quite challenging. A small error might lead to a major defect.

Tips for effective arc welding include maintaining a steady hand. This helps ensure even penetration. Use the right electrode type for your specific material. Inconsistent settings can cause issues in the weld seam. Always clean the surfaces before welding. Dirt can lead to weak bonds.

Another important aspect is managing heat input. Too much heat can warp materials. Conversely, too little may lead to weak connections. Regularly inspect your work. Detecting flaws early saves time and resources. Welding in aerospace is not just a skill; it’s an art that requires constant learning and adjustment.

TIG welding, or tungsten inert gas welding, is a refined method widely used in aerospace applications. This technique offers precision and control, vital for the demanding standards of the industry. Welders use a non-consumable tungsten electrode to produce the weld. The ability to focus heat on a small area allows for incredibly accurate work. However, this also means that the welder must be highly skilled.

One challenge with TIG welding is the necessity for a steady hand. Any slight movement can lead to inconsistencies in the weld. In addition, the process can be slower than other methods, which may not always be ideal in high-pressure environments. Mitigating these drawbacks requires practice and a keen eye for detail.

Furthermore, controlling the heat input is crucial. Too much heat can warp the material, while too little may result in a weak joint. Welders often experiment with techniques to find the perfect balance. Each piece must be treated with care, and even experienced welders can face difficulties. The potential for improvement is immense, making each project a learning opportunity.

| Welding Technique | Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| TIG Welding | A precise welding technique that uses a non-consumable tungsten electrode | Sheet metal, critical components | High quality welds, precise control | Slower compared to other methods, requires skill |

| MIG Welding | Uses a consumable wire to create the weld | Manufacturing large components, assembly lines | Faster and suitable for thick materials | Less precise, more cleanup required |

| Electron Beam Welding | Uses a beam of high-energy electrons in a vacuum | Aerospace structures, high-stress components | Deep penetration, minimal distortion | Expensive equipment, high skill required |

| Laser Welding | Uses a concentrated laser beam to melt the material | Thin materials, precision parts | High speed, minimal heat affected zone | High initial cost, complexity |

| Friction Stir Welding | Joining metals by frictional heat generated by stirring | Aluminum structures, aerospace fuselage | No fumes, strong joints | Limited to certain materials, slower process |

MIG welding is a popular choice in aerospace. Its efficiency makes it ideal for various components. The process involves feeding a continuous wire electrode through a welding gun. An inert gas shields the weld, preventing contamination. This results in strong, clean joints critical for safety in aerospace applications.

Tips: Always check for proper gas flow. Insufficient gas can lead to oxidation. It’s crucial to maintain equipment regularly. A well-maintained welder operates smoothly and produces better results.

Aerospace components often require precision. MIG welding allows for quick adjustments during operation. This flexibility can save time. However, inconsistencies in technique can cause issues. It's important to practice regularly. Experience improves overall welding quality. Perfecting MIG welding takes patience.

Friction Stir Welding (FSW) has emerged as a groundbreaking technique in aerospace assembly. This method involves a rotating tool that generates friction, which heats and softens the materials without melting them. The result is a strong, reliable bond ideal for aircraft structures. Engineers appreciate its effectiveness for aluminum alloys, commonly used in aerospace frameworks.

One key advantage of FSW is its ability to join thick materials. Traditional welding can struggle with thicker sections. FSW produces welds with minimal defects. However, challenges still exist. The process requires precise control over various factors, like temperature and tool speed. Achieving consistency can be tricky. Variations in these parameters can affect the final product's integrity. The industry constantly seeks improvements, but there’s always room for refinement.

Incorporating FSW into aircraft assembly enhances structural integrity while reducing weight. Lighter components mean improved fuel efficiency. That’s a crucial factor in modern aerospace design. Yet, the learning curve for new technicians can be steep. Skills must be honed over time. Mistakes during initial training can lead to defects later. It’s a balancing act of innovation and precision that continues to challenge engineers in the field.