Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

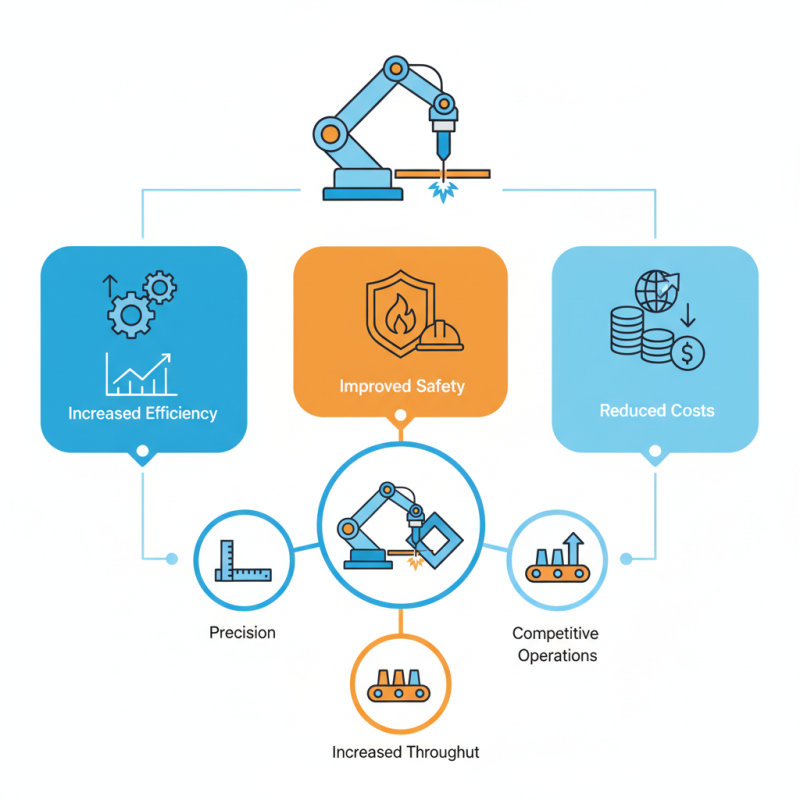

The integration of advanced technologies in manufacturing processes has revolutionized the industry, ushering in a new era of efficiency and precision. One prominent innovation leading this transformation is the Flame Cutting Robot, a tool that has gained significant attention for its ability to enhance cutting processes in modern manufacturing environments. By automating flame cutting tasks, these robots not only streamline production but also contribute to improved safety and lower operational costs.

Flame Cutting Robots offer a multitude of benefits that can greatly impact manufacturing efficiency. Their precision ensures that cuts are made with accuracy, reducing material waste and optimizing resource use. Additionally, the integration of these robots into production lines allows for increased throughput, enabling companies to meet growing demand without sacrificing quality. As the manufacturing landscape continues to evolve, the adoption of Flame Cutting Robots represents a strategic move toward more innovative and competitive operations.

Flame cutting robots have revolutionized modern manufacturing processes by delivering unmatched precision and efficiency. One of the most significant advantages of using these advanced machines is their remarkable ability to execute intricate cuts with minimal margins for error. By employing precise control algorithms and advanced sensors, flame cutting robots can maintain a consistent cutting depth and angle, which leads to higher-quality finished products. This precision allows manufacturers to reduce waste, lower material costs, and enhance overall operational efficiency.

Moreover, the enhanced precision provided by flame cutting robots translates directly into improved productivity. With their ability to operate continuously and at high speeds without succumbing to fatigue, these robots can complete tasks that would typically take human workers considerably longer. This not only accelerates production timelines but also enables manufacturers to meet tight deadlines and respond swiftly to market demands. By integrating flame cutting robots into their processes, companies are not only optimizing their output but also achieving a competitive edge in an increasingly demanding manufacturing landscape.

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Enhanced Precision | Flame cutting robots provide high accuracy in cutting materials, reducing waste and improving product quality. | Increased yield and lower material costs. |

| Consistency | Automated cutting ensures uniform results across all pieces, maintaining high standards of quality. | Reduced rework and improved customer satisfaction. |

| Increased Productivity | Robots can operate continuously without breaks, significantly speeding up production rates. | Higher throughput and faster time-to-market for products. |

| Safety | Reducing human intervention in hazardous cutting processes enhances workplace safety. | Fewer workplace injuries and associated costs. |

| Flexibility | Robots can be programmed for various cutting tasks, adapting to changing production needs quickly. | Improved responsiveness to market demands. |

| Cost Efficiency | Lower labor costs and minimized material waste contribute to overall cost savings. | Increased profitability for manufacturers. |

The implementation of flame cutting robots in modern manufacturing processes has significantly transformed production speed and efficiency. These advanced machines utilize high-temperature torches to cut through various materials with precision and speed that human operators cannot consistently achieve. By automating the cutting process, manufacturers can significantly reduce the time required for each project, allowing for quicker turnaround times and increased output. This efficiency leap is particularly beneficial in industries where time-sensitive production is crucial.

Furthermore, the integration of flame cutting robots enhances overall efficiency metrics in production lines. By minimizing human intervention, companies can reduce the incidence of errors that often lead to material waste or rework. The consistent quality of cuts ensures tighter tolerances, which is essential for industries that require precise parts for assembly. As a result, not only does this technology streamline operations, but it also contributes to better resource management by optimizing material usage. Ultimately, the adoption of flame cutting robots fosters a more dynamic and responsive manufacturing environment, poised to meet the demands of contemporary markets.

The integration of flame cutting robots in modern manufacturing processes offers significant cost reductions, primarily through automation. According to a report by the International Federation of Robotics (IFR), the use of industrial robots in manufacturing has increased productivity by as much as 30%, translating to substantial savings in labor costs and operational expenses. Automation in flame cutting means that manufacturers can reduce manual labor requirements, minimize human error, and optimize the use of materials. A study by McKinsey & Company highlights that companies that adopted advanced automation technologies, including flame cutting robots, have reported at least a 20% reduction in operational costs.

Furthermore, flame cutting robots enhance efficiency by operating continuously and consistently, which reduces downtime associated with manual processes. Research indicates that automated flame cutting systems can achieve cutting speeds that are 2-3 times faster than traditional methods, allowing manufacturers to fulfill orders more rapidly and improve turnaround times. As a result, the enhanced throughput not only augments production capabilities but also contributes to lower costs per unit, making it a financially sound investment for businesses aiming to maintain a competitive edge in the fast-evolving market. These advancements indicate that with the shift towards automation, modern manufacturing is likely to witness ongoing cost reductions and improved profitability.

Furthermore, flame cutting robots enhance efficiency by operating continuously and consistently, which reduces downtime associated with manual processes. Research indicates that automated flame cutting systems can achieve cutting speeds that are 2-3 times faster than traditional methods, allowing manufacturers to fulfill orders more rapidly and improve turnaround times. As a result, the enhanced throughput not only augments production capabilities but also contributes to lower costs per unit, making it a financially sound investment for businesses aiming to maintain a competitive edge in the fast-evolving market. These advancements indicate that with the shift towards automation, modern manufacturing is likely to witness ongoing cost reductions and improved profitability.

Flame cutting robots have revolutionized safety standards in industrial environments, significantly reducing the risks associated with manual cutting processes. According to a report by the International Federation of Robotics, the introduction of automation in manufacturing has led to a 30% decrease in workplace injuries over the last decade. This impressive statistic highlights how integrating flame cutting robots can mitigate hazards such as accidental burns, cuts, and exposure to harmful fumes that often accompany traditional cutting methods. By taking humans out of the direct line of danger, these robots not only enhance operational efficiency but also promote a safer work atmosphere.

Furthermore, the use of flame cutting robots contributes to improved consistency and precision in manufacturing processes, which indirectly enhances safety. A study from the Fabricators & Manufacturers Association revealed that inaccuracies in manual cutting can lead to rework, residual waste, and, in some cases, dangerous mishaps. With robots performing flame cutting tasks, the fallback on error-prone human handling is minimized, ensuring that materials are processed correctly the first time. This optimization not only saves time and resources but also fosters an environment where safety protocols are easily adhered to, further diminishing the possibility of workplace accidents attributed to human error.

Traditional flame cutting methods have long been a staple in manufacturing processes, particularly for high-thickness materials. However, recent advancements in robotic flame cutting technology have led to substantial improvements in efficiency, precision, and overall outcomes in manufacturing. According to a report by the International Federation of Robotics, the adoption of robotic systems in industrial operations can enhance productivity by up to 30%. This leap in efficiency is primarily due to the robots' consistent performance and reduced downtime compared to manual flame cutting, where human error can introduce variability and imperfection in the process.

Moreover, the precision of robotic flame cutting significantly outshines traditional techniques. Industry research indicates that robotic systems can achieve a cutting tolerance of ±0.5 mm, whereas manual methods often fall short, with tolerances exceeding ±1.5 mm. This higher degree of accuracy not only improves the quality of the final products but also minimizes material waste, leading to cost savings and a more sustainable manufacturing process. As industries strive for lean manufacturing practices, the adoption of robotic flame cutting presents a compelling case for modern manufacturing operations looking to elevate their production capabilities while maintaining high-quality standards.