Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the rapidly evolving landscape of manufacturing, selecting the right CNC cutting machines is crucial for optimizing productivity and precision. As industries increasingly adopt advanced automation technologies, understanding the various types of CNC cutting machines available is more important than ever. This guide aims to provide insights and practical tips for making informed choices in 2023, ensuring your business stays competitive in a technology-driven market.

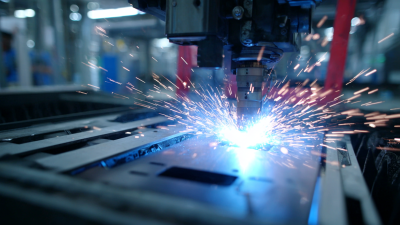

CNC cutting machines come in a myriad of forms, each designed to cater to specific materials and applications. From laser cutters to waterjet cutting machines, the diversity in technology can be overwhelming. It is essential to analyze the unique needs of your projects, including material types, thicknesses, and desired tolerances, to choose the most suitable option. Moreover, keeping abreast of industry trends and innovations will empower you to leverage cutting-edge solutions that can streamline operations and enhance output quality.

By exploring the intricacies of CNC cutting machines, this guide will present not only the fundamental aspects of selecting the right equipment but also expert insights to aid manufacturers in making strategic decisions. As the demand for precision and efficiency grows, understanding the nuances of CNC technology will be pivotal in maintaining a competitive edge in the ever-changing manufacturing sector.

When selecting the right CNC cutting machine, understanding the various types available is crucial for achieving optimal results. CNC machines can be categorized into several types, including plasma, laser, waterjet, and CNC milling machines, each serving unique purposes and applications. Plasma cutters are known for their speed and efficiency in slicing through thick metals, while laser cutters offer precision for detailed work in thinner materials. Waterjet cutters, on the other hand, utilize high-pressure water mixed with abrasives to cut through virtually any material without thermal distortion.

The market for CNC machines is rapidly evolving, partly driven by advancements in digital manufacturing technologies. This evolution allows for increased productivity across multiple industries, from aerospace to automotive and beyond. The demand for these machines reflects a growing need for customization and precision in production processes. As companies seek to enhance their capabilities, investing in the right type of CNC cutting machine becomes a strategic advantage, emphasizing the importance of understanding the diverse options available.

When selecting CNC cutting machines for your business, it is crucial to evaluate several key features that can significantly impact your manufacturing efficiency and output quality. First, consider the type of material you will be cutting. Different CNC machines are designed for various materials, including metals, plastics, and wood.

Ensuring that the machine is compatible with your intended materials will avoid complications down the line.

Additionally, the precision and speed of the CNC machine are vital metrics to assess. Look for machines that offer high accuracy and rapid processing capabilities to meet production demands. For instance, a machine with a high feed rate and low tolerance can enhance productivity without sacrificing quality.

Lastly, pay attention to the machine’s software integration and user interface. A machine that is compatible with advanced design software can streamline your workflow, making it easier to translate designs into precise cuts. Investing in a user-friendly interface can also reduce the learning curve for new operators, allowing for smoother implementation in your production line.

When assessing your production needs to choose the right CNC cutting machines, it’s essential to align your business goals with machine capabilities. Understanding the specific applications and materials you will work with can significantly influence your decision. For example, if your production primarily involves complex geometries often found in aerospace components, you'll need a machine that supports intricate designs and higher precision.

Tips for selecting the correct CNC machine include evaluating the machine’s speed and accuracy in relation to your production volume. If high throughput is your goal, consider machines that offer rapid production cycles while maintaining quality. Additionally, look for technology that can integrate with your existing systems to streamline operations, enhancing efficiency. As companies adapt to the evolving landscape of advanced industries, the right machinery can not only meet current demands but also support future growth.

Moreover, consider the ease of use and maintenance of the machines, as these factors will directly impact operational uptime. Engaging with manufacturers or industry experts can provide insights into the latest innovations and proven solutions, making sure your investment is sustainable and aligned with your business objectives.

In 2023, the CNC cutting technology landscape is experiencing significant innovations, driven by emerging trends that are reshaping the industry. One notable trend is the integration of artificial intelligence in CNC machines, which enhances precision and efficiency in multi-axis machining processes. As businesses increasingly demand high-precision components, the adoption of AI technologies is expected to propel the CNC machine tools market, estimated to grow by USD 21.9 billion from 2025 to 2029.

Moreover, laser cutting technology continues to evolve, with newer techniques providing faster and more accurate processing of materials. The rise of startups in this domain indicates a thriving ecosystem conducive to innovation, as around 20 of the 680+ startups are pioneering advancements that could significantly impact manufacturing processes. As these trends unfold, industries must stay alert to leverage new technologies effectively, ensuring they remain competitive in the ever-evolving market landscape.

| Feature | Description | Emerging Trend 2023 |

|---|---|---|

| Cutting Technology | The method used for cutting materials, including laser, plasma, or waterjet. | Increased adoption of hybrid cutting technologies. |

| Machine Size | Physical dimensions and cutting capacity of the CNC machine. | Trend towards more compact machines without sacrificing performance. |

| Software Compatibility | Integration with design software for efficient workflow. | Rise of cloud-based software solutions for remote access. |

| Material Versatility | Ability to cut different types of materials. | Increased performance on composite and advanced materials. |

| Automation Features | Integration of automated loading and unloading systems. | Growth in fully automated cutting systems for higher efficiency. |

| Cost of Ownership | Initial investment as well as operational costs over time. | Focus on machines that offer lower total cost of ownership. |

When budgeting for CNC cutting machines in 2023, it is essential to consider various cost factors that impact overall investments. Initially, potential buyers should evaluate their production needs and the specifications of the machines, as these will significantly influence the purchase price. The cost of materials, labor, and operating expenses must also be factored in. Researching the market for different machine brands and models can provide insight into price ranges and help in making an informed decision.

Additionally, maintenance and operational costs should not be overlooked. Regular maintenance can prevent costly repairs and downtime, so allocating a portion of the budget for routine checks and replacements is crucial. Furthermore, considering the potential for automation and advanced technology in CNC cutting machines can lead to higher upfront costs but may yield long-term savings through improved efficiency and reduced labor costs. By carefully analyzing these financial aspects, businesses can make strategic investments that align with their growth and production goals.