Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In recent years, the demand for Extended Type Cobots has surged across various industries. According to a report by the International Federation of Robotics, the cobot market is expected to reach $12 billion by 2025. This rapid growth highlights the critical need for companies to choose the right Extended Type Cobot for their specific applications.

Dr. Emily Johnson, a leading expert in automation, emphasizes, "Selecting the right cobot is not just about functionality; it's about aligning it with your business goals." Companies face challenges in identifying cobots that fit their processes. The specifications may seem overwhelming, but understanding your operational needs can guide your decision.

It's also essential to acknowledge that not all Extended Type Cobots are created equal. Businesses must reflect on their unique requirements and potential limitations. This thoughtful approach may lead to better integration and improved productivity. Investing time in research will ultimately yield greater returns in the fast-evolving automated landscape.

Extended type cobots, or collaborative robots, play a vital role in modern manufacturing and automation. Understanding their basics is crucial for effective utilization. Cobots are designed to work alongside humans. They often feature advanced sensors and user-friendly interfaces. This allows operators to collaborate safely and efficiently. They can handle various tasks, from assembly to material handling.

When choosing a cobot, consider specific needs. Think about the tasks they will perform. The weight they need to lift is essential. Reach and flexibility are also important factors. However, choosing the wrong model can lead to inefficiencies. Some cobots may not integrate well with existing systems. Others may lack the precision needed for specific tasks. Evaluating options thoroughly can save time and resources.

Training users on cobots is often overlooked. While cobots are designed for ease of use, proper training is necessary. Employees may feel intimidated by new technology at first. They may resist the change. Addressing these concerns can ease the transition. Communication and support are key to unlocking the full potential of cobots in any workspace.

When identifying your specific automation needs, start by assessing your workflow. Consider the tasks that require repetitive motion or heavy lifting. According to a report by the International Federation of Robotics, about 68% of companies use collaborative robots for tasks like assembly and packaging. Understanding your specific requirements is critical to selecting the right extended type cobot.

Evaluate the workspace where the cobot will operate. Will it work alongside humans or in isolation? This aspect affects the safety features you need. Many organizations opt for cobots with advanced sensors to minimize risks. It’s essential to balance complexity with user-friendly interfaces. If your staff struggles with the technology, the benefits may not be fully realized.

Tips: Start with a clear outline of desirable functions. Gather input from team members who will interact with the cobot daily. Reflect on any previous automation challenges you faced. Adjust your choice based on feedback and the unique needs of your operations. Spending time to get these details right can save you headaches later on.

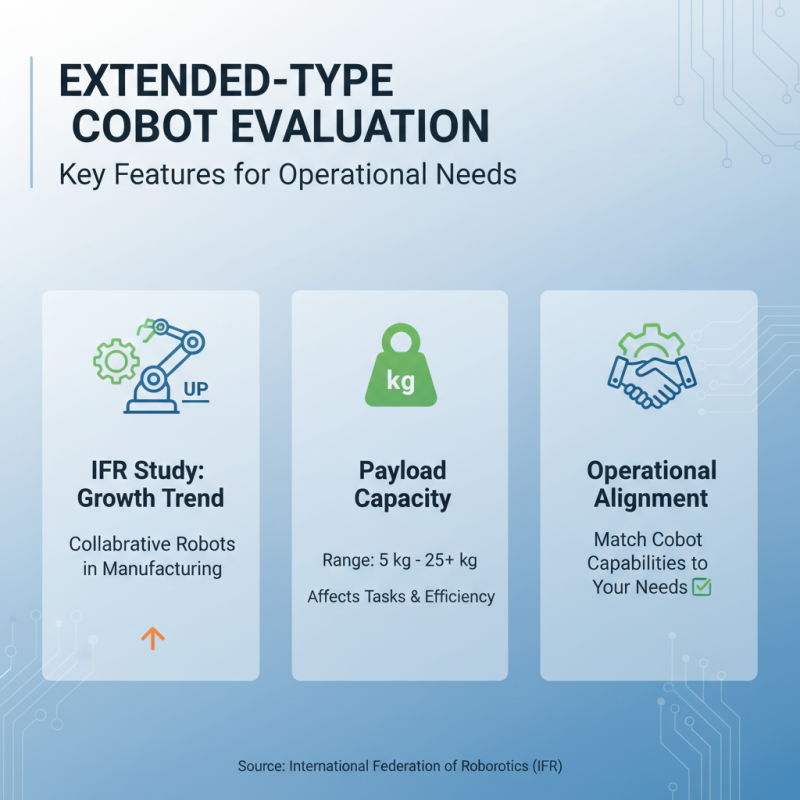

When evaluating extended type cobots, it’s crucial to focus on key features that align with your operational needs. A recent study from the International Federation of Robotics (IFR) indicates a growing trend in the adoption of collaborative robots, particularly in manufacturing. Companies are increasingly recognizing the importance of payload capacity, which can range from 5 kg to over 25 kg in some models. This range affects not only the tasks cobots can perform but also their efficiency in a mixed workload environment.

Another critical aspect is the ease of programming. Many cobots now come with user-friendly interfaces that allow for quick setup and operation. Research shows that nearly 70% of users prefer intuitive programming methods, which can reduce the time needed for training. However, while these interfaces are beneficial, they may not cover complex use cases which require advanced configuration. This limitation may hinder some operators from fully utilizing the cobot's potential.

Additionally, safety features cannot be overlooked. Extended cobots often include advanced sensors and adaptive safety systems that allow them to operate alongside human workers. However, a report by the Robotics and Automation Society highlights that 34% of workplace accidents still involve cobots. This statistic underscores the need for thorough risk assessments before implementation. It's essential to weigh these considerations carefully to ensure a cobot serves its intended purpose without compromising safety or productivity.

When evaluating cobots, cost is a major factor. A report from the International Federation of Robotics states that the average price of these collaborative robots is around $40,000. This upfront cost may seem high, but it's essential to consider the total value they bring to manufacturing processes. For example, cobots can boost productivity by up to 85%, which translates into significant long-term savings.

Many companies overlook hidden costs. Maintenance, training, and integration can add thousands to your budget. Data suggests that around 20% of companies fail to calculate these expenses, ultimately affecting their ROI. A poorly chosen model can lead to underperformance and wasted investments.

It’s vital to analyze each model's specifications and capabilities in relation to your unique needs. Some models may excel in speed, while others focus on precision. According to recent studies, 60% of businesses reported improved efficiency after switching cobots. However, the right choice depends on individual workflow requirements. Not all solutions fit all problems.

When choosing an extended type collaborative robot (cobot), compatibility with existing systems is crucial. Many businesses rely on data that indicates over 60% of automation failures stem from poor integration. Assessing how a cobot fits into your current workflow can save time and resources.

Check your existing equipment. Consider its communication protocols and operating systems. For instance, if your machinery predominantly uses Ethernet, ensure the cobot supports it. A mismatch could lead to unnecessary challenges. Industry reports mention that seamless integration boosts productivity by 30%.

Tip: Conduct a full system audit prior to purchasing a cobot. Identify potential gaps or conflicts in technology. Engage your team and gather insights. Their experience with current workflows can highlight unseen issues.

Also, reflect on the training your team will need. Implementing a cobot might require upskilling staff. Research shows that companies investing in training see a 25% rise in overall efficiency. Ensure that the selected cobot complements human capabilities and fits naturally into daily operations.

| Feature | Cobot A | Cobot B | Cobot C |

|---|---|---|---|

| Payload Capacity | 5 kg | 10 kg | 15 kg |

| Reach | 600 mm | 900 mm | 1200 mm |

| Repeatability | ±0.05 mm | ±0.1 mm | ±0.05 mm |

| Power Supply | 220V AC | 110V AC | 220V AC |

| Communication Protocols | Ethernet, USB | Ethernet, RS-232 | USB, RS-485 |

| Ease of Integration | High | Medium | High |

| User-Friendly Interface | Yes | Yes | No |