Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

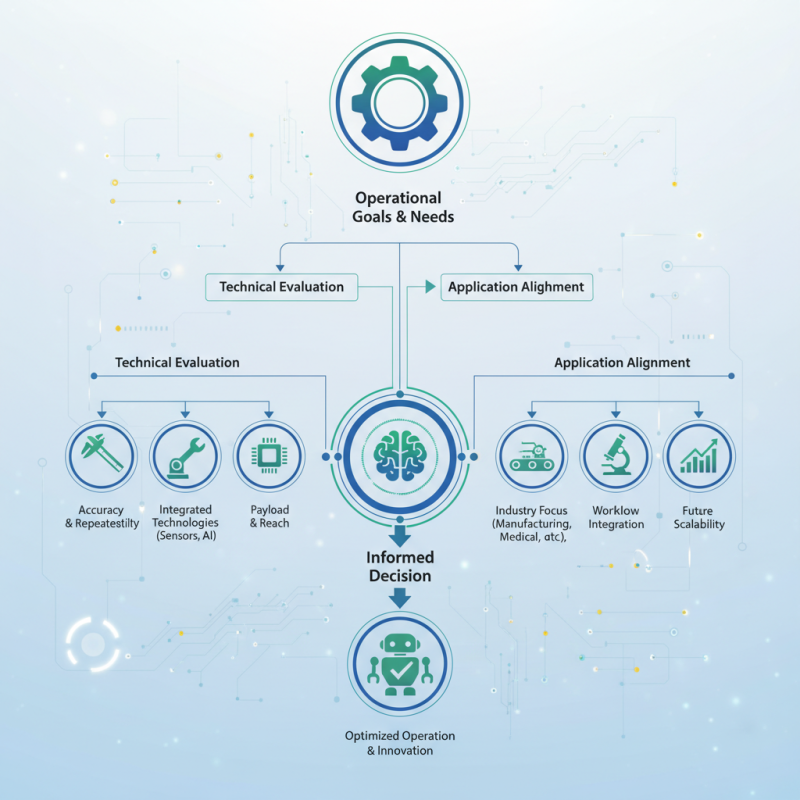

As industries continue to evolve and the demand for automation grows, choosing the right high precision robot has become a critical decision for businesses aiming to enhance productivity and quality. In 2025, the advancements in technology and robotics will create a wide array of options, making it essential to understand the specific needs of your application before making a selection. According to Dr. Emily Huang, a leading expert in robotics and automation, "Selecting the appropriate high precision robot is not just about specifications; it's about aligning technology with your operational goals."

With applications ranging from manufacturing to medical fields, the importance of precision in robotic systems cannot be overstated. High precision robots offer unparalleled accuracy and consistency, which are vital for tasks that require meticulous attention to detail. However, the variety of models and features available can often lead to confusion. It is crucial for companies to evaluate not only the technical specifications but also how these robots can seamlessly integrate into existing workflows.

In this guide, we will explore the key factors to consider when selecting a high precision robot, ensuring that your choice not only meets current demands but also positions your organization for future success. By understanding your unique requirements and the potential of robotics, you can make an informed decision that enhances your operational efficiency and drives innovation.

As we approach 2025, the high precision robotics market is poised for significant transformation driven by advancements in technology and evolving industry needs. One prominent trend is the increasing integration of artificial intelligence and machine learning into robotic systems, enhancing their adaptability and efficiency. This shift not only improves precision in manufacturing and assembly tasks but also enables robots to learn from their environments, making them capable of performing complex tasks with minimal human intervention. Companies seeking to leverage this technology will find that investing in robots equipped with AI capabilities can yield substantial productivity gains.

Another noteworthy market trend is the burgeoning demand for collaborative robots, or cobots, which work alongside human operators. These robots are designed to be safe in shared environments, allowing for smoother interactions and more streamlined workflows. As industries move towards automation, the focus is shifting from purely high-speed operations to systems that prioritize safety, flexibility, and user-friendliness. This evolution reflects a broader understanding of the vital role that humans play in industrial processes, leading to robots designed to complement human work rather than replace it. Companies must recognize these trends and assess their unique operational needs to select high precision robots that not only meet technical specifications but also align with their organizational goals.

| Robot Type | Max Payload (kg) | Precision (mm) | Application Area | Market Price (USD) |

|---|---|---|---|---|

| Articulated Robot | 10 | 0.03 | Assembly | 25,000 |

| SCARA Robot | 5 | 0.01 | Pick and Place | 15,000 |

| Delta Robot | 3 | 0.005 | Food Packaging | 20,000 |

| Collaborative Robot (Cobot) | 4 | 0.02 | Light Assembly | 12,000 |

| Cartesian Robot | 15 | 0.1 | Material Handling | 18,000 |

When selecting a high precision robot in 2025, understanding the key specifications is crucial to make an informed decision. One of the primary specifications to consider is the robot's repeatability and precision levels. According to a report by the International Federation of Robotics, the demand for high precision robots has surged by over 40% in manufacturing sectors, largely driven by the need for enhanced accuracy in processes such as assembly and quality control. Typically, high precision robots offer repeatability of ±0.01 mm, making them indispensable for industries such as electronics and medical devices.

Another critical specification to evaluate is the robot's payload capacity and range of motion. A study published by MarketsandMarkets analyzed the robotics market and projected that by 2025, more than 50% of industrial robots will be equipped with advanced payload capabilities. This advancement is essential for applications that require handling delicate components or operating in tight spaces. Additionally, the integration of advanced sensors and machine learning technology is becoming increasingly common, enabling robots to adapt to various tasks and optimize their performance dynamically.

Finally, consider the ease of programming and integration with existing systems. Many robotic solutions now offer user-friendly interfaces and compatibility with popular programming languages, which significantly reduces setup time. According to a survey from Robotics Business Review, over 70% of manufacturers reported that ease of integration was a deciding factor in selecting robotic solutions. This trend reinforces the importance of choosing a robot that not only meets precision requirements but also aligns with your operational workflows.

The demand for high precision robots is steadily increasing across major industries as they strive for improved efficiency and accuracy. According to a recent report by the International Federation of Robotics (IFR), the global market for industrial robots is expected to grow by 12% annually from 2021 to 2025, driven by sectors such as electronics, automotive, and medical devices. These industries require high-precision automation to meet the escalating expectations for product quality and consistency. As manufacturers face labor shortages and rising costs, investing in precision robotics becomes a vital strategy for maintaining competitive advantage.

In the electronics industry, for example, high precision robots are essential for tasks such as micro-manipulation and assembly of sensitive components, where even the smallest error can lead to product defects. A study by McKinsey & Company highlights that automating these processes can boost production efficiency by up to 30%. Similarly, the medical device sector is experiencing heightened demand for precision robotics, particularly in surgical applications, where precision can be a matter of life and death. The global market for surgical robots is projected to reach $20 billion by 2025, driven by technological advancements and increasing investment in health care.

Tips: When evaluating high precision robots for your needs, consider not only the technical specifications but also the ease of integration into your existing systems. It’s crucial to assess your specific application requirements and future scalability. Another tip is to look for robots that offer advanced programming capabilities, allowing for greater flexibility in varying production tasks as demands evolve.

When selecting a high precision robot for industrial applications in 2025, conducting a thorough ROI analysis is crucial. Evaluating the cost versus performance of various robotic solutions can significantly influence operational efficiency and profitability. According to a recent report from the International Federation of Robotics, the demand for high precision robots is projected to grow by 25% annually, underlining the importance of making informed decisions. Businesses should focus not only on the initial purchase price but also on how the robot's accuracy and reliability can enhance production processes and reduce waste.

Tips for evaluating ROI include analyzing the expected increase in production rates and reductions in error margins. For instance, if a high precision robot can improve product quality by even 5%, this can lead to substantial savings over time. Additionally, it’s imperative to assess maintenance costs, as advanced robotics may require specialized support that could impact your long-term budget. The total cost of ownership should encompass energy consumption, downtime, and any necessary training for staff to operate sophisticated systems efficiently.

Finally, consider benchmarking performance by examining case studies within your industry. Research indicates that companies integrating high precision robotics experience a return on investment within 18 to 24 months, especially when enhanced precision leads to shorter lead times and better customer satisfaction rates. As you navigate through options, keeping these metrics in mind will facilitate a more strategic selection that aligns with both current needs and future growth potential.

This chart compares the costs and performance of various high precision robots available in 2025. The first dataset represents the cost in dollars, while the second dataset indicates their precision in millimeters. This analysis helps potential buyers evaluate which robot offers the best return on investment based on their specific precision needs.

In 2025, as industries increasingly turn to automation, selecting the right high-precision robot necessitates a thorough evaluation of how well it integrates and is compatible with existing systems. According to a recent industry report by the International Federation of Robotics, approximately 70% of industrial operations will require seamless integration between new robotic systems and existing machinery to enhance productivity and reduce operational downtime.

One key aspect to consider is the communication protocols of the robot. Ensuring that a new robot can effectively communicate with existing systems can significantly influence overall efficiency. For instance, robots that utilize common communication standards such as OPC UA or ROS have demonstrated enhanced interoperability with various industrial equipment while minimizing integration costs.

Tips: When assessing robots, prioritize those that provide robust API documentation and support various software platforms. Additionally, engage with vendors that offer extensive customization options to tailor integration features to your specific operational needs. A comprehensive compatibility assessment will enable smoother transitions and optimize your automation strategies moving forward.