Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

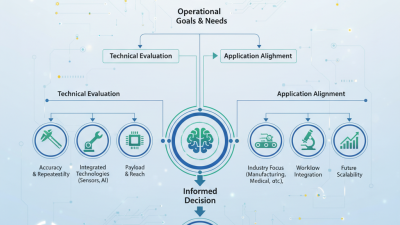

In the rapidly evolving world of automation, selecting the right High Precision Robot is crucial for many industries. These robots enhance productivity and accuracy. According to a recent report by MarketsandMarkets, the global high precision robotic market is projected to reach $5.2 billion by 2026, indicating a significant growth trend. Companies must carefully evaluate their specific needs to maximize this investment.

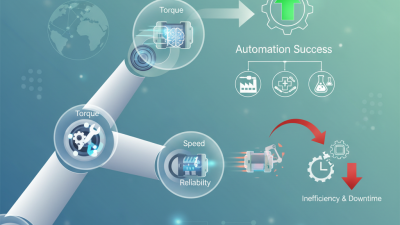

Dr. Emily Rodriguez, a leading expert in robotics, states, “Choosing a High Precision Robot is about matching technology with application.” Each manufacturing process has unique requirements, such as speed, payload capacity, and environmental factors. Consideration should also be given to potential integration challenges. Not every robot will fit every task, and an ill-suited choice can lead to inefficiencies.

Investing in high precision technology requires reflection on multiple factors. For example, training employees on new robotic systems is essential for ensuring seamless operations. Moreover, the balance between cost and quality must be analyzed carefully. Making the right choice can yield tremendous benefits, but overlooking crucial elements may result in setbacks.

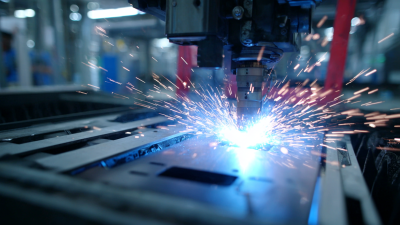

High precision robots are crucial in various industries, including manufacturing and healthcare. They play a vital role in tasks that require accuracy and repeatability. Understanding high precision robots involves grasping key terms like resolution, accuracy, and payload capacity. These definitions shape how we analyze and select suitable robots.

When considering applications, it's important to explore their specific functions. For instance, these robots can perform intricate surgeries or assemble delicate electronic components. Precision is critical in both cases. However, one must reflect on the training needed for operators. It's not simply about technology; human factors matter too. Operators may struggle initially, requiring time to master the equipment.

Every application has unique challenges. Inconsistent results can occur due to external factors like environmental conditions. Lighting and temperature might affect performance, leading to varied outcomes. It's essential to consider potential variables that could disrupt precision. Assessing these factors can guide better decision-making for your robotics needs. The journey isn't always straightforward, but understanding these nuances is key to success.

Choosing the right high precision robot involves understanding precision requirements. Different industries have specific standards and metrics that define precision. For example, in the medical field, even minute errors can lead to severe consequences. Thus, precision must meet stringent regulations. In manufacturing, tolerances might be less strict, but still critical for quality.

Evaluating precision means considering factors like repeatability and accuracy. Repeatability refers to a robot’s ability to return to the same position. Accuracy measures how close the robot’s position is to the desired target. These metrics help determine if a robot will meet operational goals. Often, a robot may excel in one metric but fall short in another.

Cost is also a consideration. Higher precision typically comes with a higher price tag. It’s essential to assess whether the added precision justifies the expense. Reflecting on these elements can lead to better decision-making. Ultimately, understanding requirements is key to success in automation.

When selecting a high precision robot, understanding payload capacity is vital. Each task requires that the robot can handle specific weights and shapes. A mismatch in payload capacity can lead to underperformance, or worse, damage.

Consider the types of materials you will be processing. Are they heavy, fragile, or oddly shaped? Knowing this helps narrow down options. For instance, a robot suited for light components might struggle with heavy items. Always check the robot's specifications for payload limits. It should align with your operational requirements.

**Tip 1:** Pay attention to the robot's specifications. Analyze how much it can lift versus what you need. Don’t underestimate this.

Think about future tasks as well. Your needs may evolve, and so should your robot’s capabilities. Be mindful that higher payload capacity often comes with higher costs. Will you need that extra capacity later on? If your current tasks don’t require it, a lesser model might be sufficient.

**Tip 2:** Don’t rush. Spend time reviewing different options. Evaluate how each robot can meet your current and future tasks.

Recognizing the interplay between payload and tasks is essential. This task-specific approach can ensure a more effective and reliable operation. If you feel overwhelmed, that’s okay. It’s essential to reflect on your requirements and decisions.

Choosing the right high precision robot can seem overwhelming. The options are vast. Different types serve various purposes. Understanding your specific needs is crucial. Start by considering what tasks the robot will perform. Is it for assembly, inspection, or another application? The accuracy requirements will vary based on the task.

When evaluating robots, take note of their specifications. Some robots excel in speed, while others focus on precision. Look for robots with adequate payload capacity for your tasks. If your processes involve delicate components, a lightweight robot may be best.

**Tips:**

Assess the environment where the robot will operate. Will it be in a clean room or a harsh factory setting? Don’t overlook ease of programming. Complex interfaces can slow down deployment.

Reflect on potential future needs. Flexibility is essential in a rapidly evolving market. A robot that fits your current tasks may lack adaptability. Keep an open mind to new technologies. Examine case studies to see how others have succeeded or faced challenges. Adapt your strategy based on their experiences.

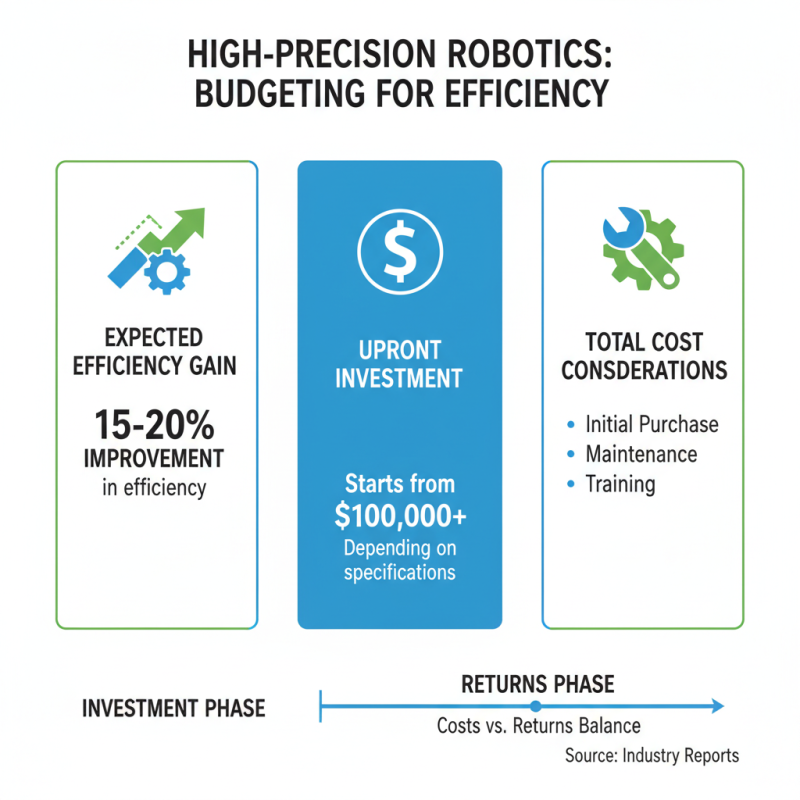

In the world of high precision robotics, budget remains a crucial factor. Many businesses grapple with the initial costs versus expected returns. Reports indicate that companies often expect a 15-20% improvement in efficiency when adopting high precision robots. Upfront investments can be significant, sometimes reaching $100,000 or more depending on the specifications. Evaluating total costs can be complex. Hidden expenses like maintenance and training add to the overall budget.

Return on investment (ROI) analysis is essential for informed decisions. Studies show that industries utilizing precision robotics see a revenue increase of up to 30%. However, not all implementations yield immediate gains. Organizations need to assess specific needs and projected outcomes carefully. A robot that fits one company's operations may not work for another. Flexibility in budgets can allow for better technology adaptations down the road.

Cost efficiency isn't just about purchase price. It involves understanding the long-term benefits and risks. Some reports suggest that about 40% of robotics projects face budget overruns. Having a contingency plan can mitigate potential losses. Investing in high precision robotics demands a thoughtful approach, blending both current and future needs.