Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the rapidly evolving world of automation, selecting the appropriate Robot Arm Motor is not merely a technical decision but a crucial strategic move that can determine the success of your entire operation. As John Smith, a leading expert in robotics engineering, aptly states, "The performance of your automation system hinges on the precise control and reliability offered by the Robot Arm Motor." This assertion underscores the vital role that these motors play in ensuring that robotic arms can execute tasks with precision and efficiency.

The choice of a Robot Arm Motor influences various factors, including speed, torque, and overall performance, which directly impact productivity and operational costs. With diverse applications ranging from manufacturing to healthcare, the consequences of selecting the wrong motor can be significant, leading to inefficiencies and increased downtime. Thus, understanding the nuances of different motor types and their specific capabilities is essential for successful automation implementation.

As industries continue to embrace robotic solutions, the necessity of thoughtfully selecting a Robot Arm Motor becomes increasingly evident. Companies must prioritize this decision to enhance productivity, reliability, and ultimately, their competitive edge in the market. In an era where technology shapes business outcomes, the right motor is a cornerstone of automation success.

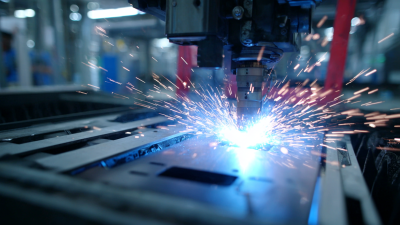

In the realm of automation systems, the significance of robot arm motors cannot be overstated. These motors serve as the backbone of robotic movements, translating electrical energy into precise mechanical actions. Selecting the appropriate motor is crucial because it directly impacts the performance, efficiency, and reliability of the entire automation setup. A well-matched motor ensures that the robot arm can operate smoothly, handle required payloads, and maintain the desired speed and accuracy during tasks.

Moreover, the quality and type of robot arm motors affect the longevity of the automation system. High-quality motors not only provide consistent performance over time but also help mitigate issues such as wear and tear, overheating, and unnecessary downtime. As automation evolves to meet increasingly complex demands, the importance of integrating robust and efficient motors has become ever more critical. This ensures that companies can achieve optimal productivity while reducing operational costs, ultimately driving greater success in their automation initiatives.

| Motor Type | Torque (Nm) | Speed (RPM) | Power Rating (W) | Efficiency (%) | Applications |

|---|---|---|---|---|---|

| Stepper Motor | 1.2 | 2000 | 30 | 85 | 3D Printing, CNC Machines |

| DC Motor | 0.8 | 3000 | 25 | 75 | Robotics, Automation |

| Servo Motor | 1.5 | 1500 | 50 | 90 | Robotic Arms, UAVs |

| Brushless Motor | 2.0 | 4000 | 60 | 92 | Electric Vehicles, Drones |

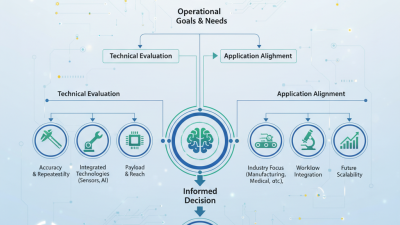

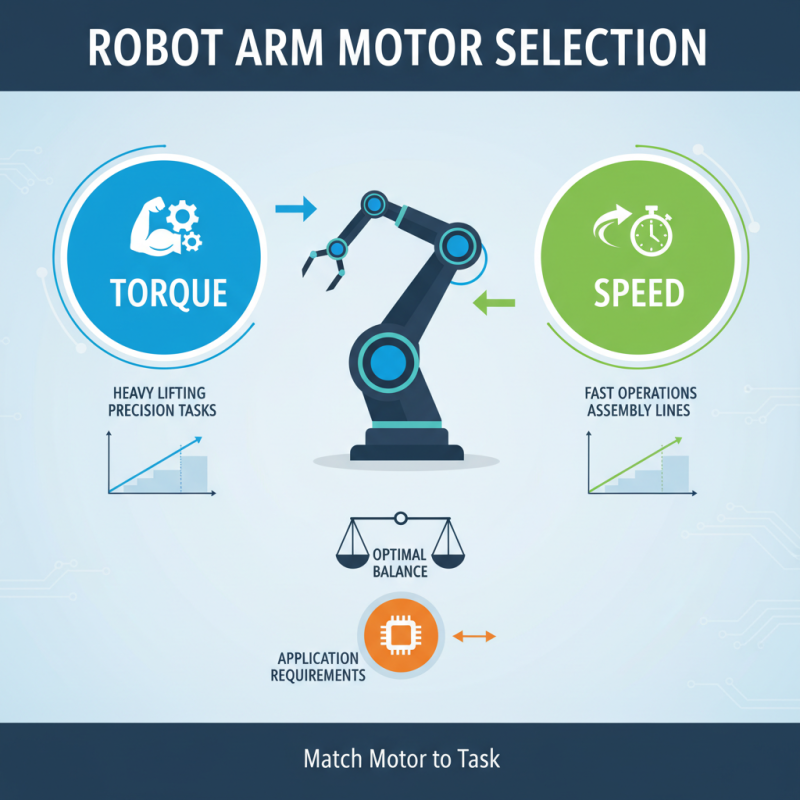

When selecting a robot arm motor, several key factors influence the decision-making process. One of the primary considerations is the motor’s torque and speed characteristics. Different applications require varying levels of precision and performance; for instance, tasks involving heavy lifting versus those that demand high-speed operations will necessitate different motor specifications. Understanding the requirements of the intended automation task can help in selecting a motor that offers the right balance of torque and speed.

Another critical factor is the motor type itself, which encompasses options such as stepper motors, servo motors, andDC motors. Each motor type has its unique benefits and drawbacks regarding control accuracy, efficiency, and responsiveness. For example, servo motors are often favored for their high precision and control capabilities, making them ideal for applications needing fine adjustments. Conversely, stepper motors are well-suited for situations where simplicity and cost-effectiveness are prioritized. Evaluating the specific needs of the robotic application in conjunction with the motor's features will significantly impact the overall success of the automation project.

When selecting a robot arm motor, performance metrics such as torque, speed, and precision play a pivotal role in determining your automation success. Torque is essential for ensuring that the motor can handle the required loads without stalling or overheating. A motor with the right torque rating will allow your robotic arm to perform heavy lifting and complex tasks effectively, making it crucial for industries that rely on strength and reliability.

Speed is another critical aspect that can greatly affect the efficiency of robotic operations. The ability of a motor to move rapidly across its range of motion can boost productivity, allowing tasks to be completed in less time. However, speed must be balanced with precision; an exceptionally fast motor that lacks accuracy may lead to errors in task execution and ultimately undermine the effectiveness of the automation process.

Tips: When choosing a robot arm motor, consider running simulations to understand how different torque and speed settings impact your operations. It's also advisable to analyze the specific tasks your robot arm will perform to determine the required precision levels. By aligning these performance metrics with your operational goals, you can ensure a well-rounded and efficient automation strategy.

The demand for advanced robot arm motors is on the rise, driven by several key industry trends. As automation becomes increasingly integral to various sectors, the need for precise, reliable, and efficient robotic solutions escalates. Industries ranging from manufacturing to healthcare are recognizing that the capabilities of robot arms hinge significantly on the performance of their motors. This heightened focus on motor technology has led to innovations that enhance speed, accuracy, and responsiveness, making them indispensable for modern automation processes.

Additionally, the push toward more intelligent and adaptable robots necessitates sophisticated motor designs that can handle complex tasks and operate in dynamic environments. Emerging trends such as collaborative robots, or cobots, are particularly influencing the development of motor technology, as these robots require motors that can securely and safely function alongside human operators. As organizations strive for greater productivity and flexibility in their operations, the evolution of robot arm motors is set to play a crucial role in shaping the future of automation across diverse industries.

When it comes to automating processes, selecting the right robot arm motor is essential for optimizing efficiency and cost-effectiveness. A cost-benefit analysis of different robot arm motor types reveals significant differences in both upfront costs and long-term operational efficiency. For instance, according to a report from the International Federation of Robotics, servo motors, while generally more expensive due to their higher precision and torque capabilities, can increase overall productivity by as much as 30%. This efficiency often justifies their initial investment for applications that require high accuracy and rapid movement.

On the other hand, stepper motors present a more budget-friendly option, with lower initial costs and decent torque at low speeds. However, they come with trade-offs, particularly in energy consumption and reduced efficiency during high-speed operations. The Association for Advancing Automation estimates that using stepper motors can result in energy costs that are 20-30% higher in certain applications, making them a less viable choice for long-term automation success in high-demand environments. Ultimately, businesses must carefully evaluate the specific demands of their applications and consider the total cost of ownership when selecting a motor type, ensuring that the choice aligns with both performance goals and budget constraints.