Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right welding material is crucial for any project. It can influence the strength, durability, and overall quality of the weld. The selection process is not always straightforward. Different applications require different materials. This can be overwhelming for beginners and even some experts.

When selecting a welding material, consider the base metals involved. Each metal has unique properties that affect how it should be welded. For instance, aluminum requires specific filler materials that differ from those used with steel. Ignoring these details can lead to weak joints or failures.

Understanding the specifics of welding materials is essential for success. A wrong choice can result in costly repairs and waste of time. Many overlook the importance of filler rods and their composition. Reflecting on your choices can refine your skills and outcomes. Knowledge of welding material is key to achieving effective and reliable results.

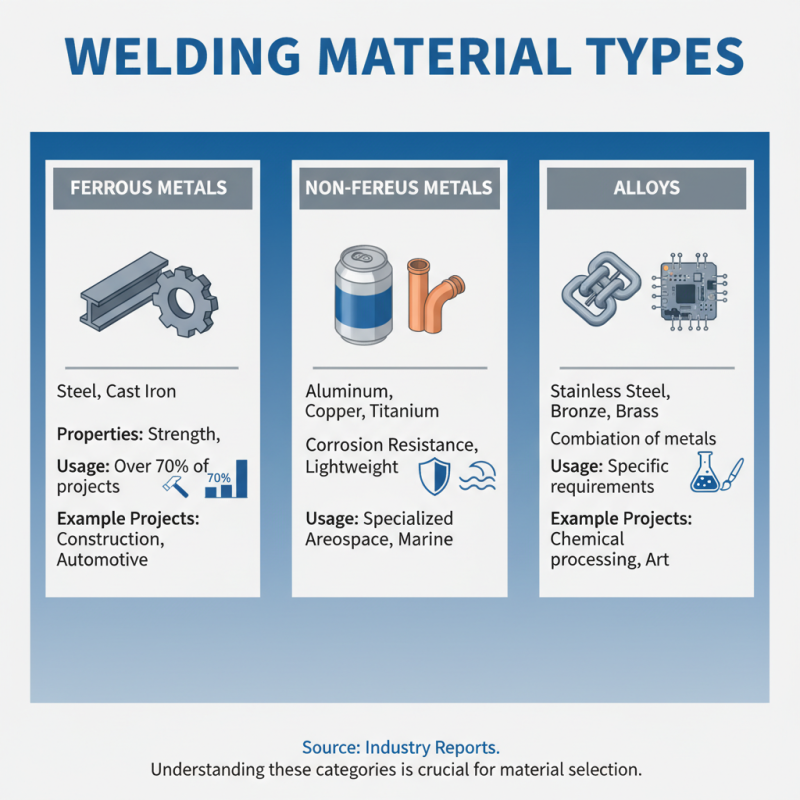

When selecting the right welding material, understanding the types available is crucial. The three primary categories are ferrous metals, non-ferrous metals, and alloys. Ferrous metals, like steel, are known for their strength and durability. According to industry reports, over 70% of welding projects involve steel due to its reliability. Non-ferrous metals, such as aluminum and copper, offer unique benefits, like resistance to corrosion, but can be challenging to weld.

Alloys provide diverse characteristics that can enhance the welding process. For instance, stainless steel alloys combine strength with resistance to oxidation. However, the complexities of alloy selection can be daunting. Data indicates that selecting the right alloy can improve weld quality by up to 50%. Many welders often overlook the specific properties needed for different applications, which can lead to costly mistakes.

Understanding the variations in these materials is essential for achieving the desired results. Each type of welding material has distinct behaviors when exposed to heat. This complexity adds an extra layer of decision-making. Knowledge gaps can lead to poor choices. It’s vital to reflect on one's material selection process and continuously seek to educate oneself about new advancements in welding materials.

Choosing the right welding material starts with understanding your project requirements. Different projects have unique needs. Factors like metal type, thickness, and environmental conditions play a crucial role. For example, you may need to use a specific type of filler if you work with stainless steel. The welding method also matters. MIG, TIG, and stick welding each require different consumables.

Consider the working environment as well. If your project happens outdoors, materials that resist oxidation might be essential. Think about the joint design too. Some may require a stronger weld, while others can use lighter materials. Reflection is important here. Have you evaluated all possible scenarios? Overlooking a minor detail can lead to complications down the line.

Safety requirements shouldn't be forgotten. Depending on the project, certain materials might pose greater risks. Assess every detail carefully. It's not just about picking the right metal; it’s about ensuring the entire process runs smoothly. Finding the perfect match is often trial and error. Learn from each project to refine your choices for the next one.

When selecting welding materials, several factors come into play. Material compatibility is crucial. Different metals often require specific electrodes and fillers. For instance, aluminum welding may need specialized wires. Choosing the wrong combination can lead to a weak joint. This is a common mistake that many new welders make.

Another key factor is the environment. Welding outdoors versus indoors can change your material choice. Wind and moisture can affect the weld quality. Additionally, the thickness of the base metals plays a role. Thicker materials may need more heat and a different type of filler. A welder must carefully consider these conditions.

Cost is also an important element. Premium materials may offer better results but can strain budgets. Finding an affordable option that meets requirements can be challenging. Often, welders must prioritize quality over price. Balancing these considerations is not easy. Many experienced welders still reflect on their past choices and learn from them.

When selecting welding materials, cost-effectiveness is crucial. Some options may appear cheaper initially but lead to higher long-term expenses. For example, lower-quality materials might require more frequent replacements. It's essential to analyze the full lifecycle cost, not just the upfront price. This often includes maintenance and potential downtime for repairs.

Availability is another key factor. A material that is inexpensive but hard to source may hinder projects. Ensure that suppliers have a steady stock. Consider local distributors when possible. This can reduce shipping costs and lead times. It also supports local economies and establishes a reliable supply chain.

Welding projects often face unexpected challenges. Material shortages can delay timelines. Relying on a single supplier can lead to risks. Diversifying your sources might incur higher initial costs but can save time. It's important to reflect on these aspects when choosing materials. Balancing cost, availability, and quality requires critical thought and ongoing evaluation.

Selecting the right welding material is crucial for safety and performance. Proper material choice impacts the integrity of the weld. According to a report by the American Welding Society, improper material can lead to weld failures in 30% of cases. This statistic highlights the need for careful consideration of materials.

Safety is paramount. Different materials have unique properties. For example, stainless steel has excellent corrosion resistance. However, it can be challenging to weld. In contrast, mild steel is easier but offers less durability. Understanding these characteristics is essential for achieving strong, safe welds. A study found that poor material selection can increase the risk of workplace accidents by 25%.

Performance also hinges on the right choice. For high-temperature applications, materials like Inconel are preferred. Yet, they can be harder to work with. Not all welders are equipped for such tasks. This mismatch can lead to poor-quality welds that fail under stress. Evaluating the skill level of the welding team against material requirements is a step often overlooked. Each choice has its pros and cons, requiring careful reflection and assessment.

| Tip No. | Tip | Material Type | Safety Considerations | Performance Notes |

|---|---|---|---|---|

| 1 | Select based on base metal | Mild Steel | Ensure proper ventilation to avoid fumes | Good for structural applications |

| 2 | Consider the welding process | Stainless Steel | Use protective gloves to prevent burns | Excellent corrosion resistance |

| 3 | Assess the thickness of materials | Aluminum | Be cautious of gas releases during welding | Lightweight and strong |

| 4 | Check for compatible alloys | Copper | Electricity hazards must be controlled | Good thermal conductivity |

| 5 | Evaluate the environment | Coated Steel | Use masks to prevent inhalation of fumes | Increased durability against elements |

| 6 | Understand mechanical properties | High Strength Low Alloy | Ensure equipment is properly maintained | Great for applications requiring strength |

| 7 | Choose proper filler materials | Nickel Alloys | Assess for toxicity during welding | Great strength at high temperatures |

| 8 | Review joining techniques | Titanium | Requires specialized equipment | Light and strong for aerospace uses |

| 9 | Consider post-weld treatments | Hastelloy | Handling must adhere to safety protocols | Excellent corrosion resistance |

| 10 | Consult professionals when unsure | Various Alloys | Keep up-to-date with safety standards | Varied applications; knowledge is key |