Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

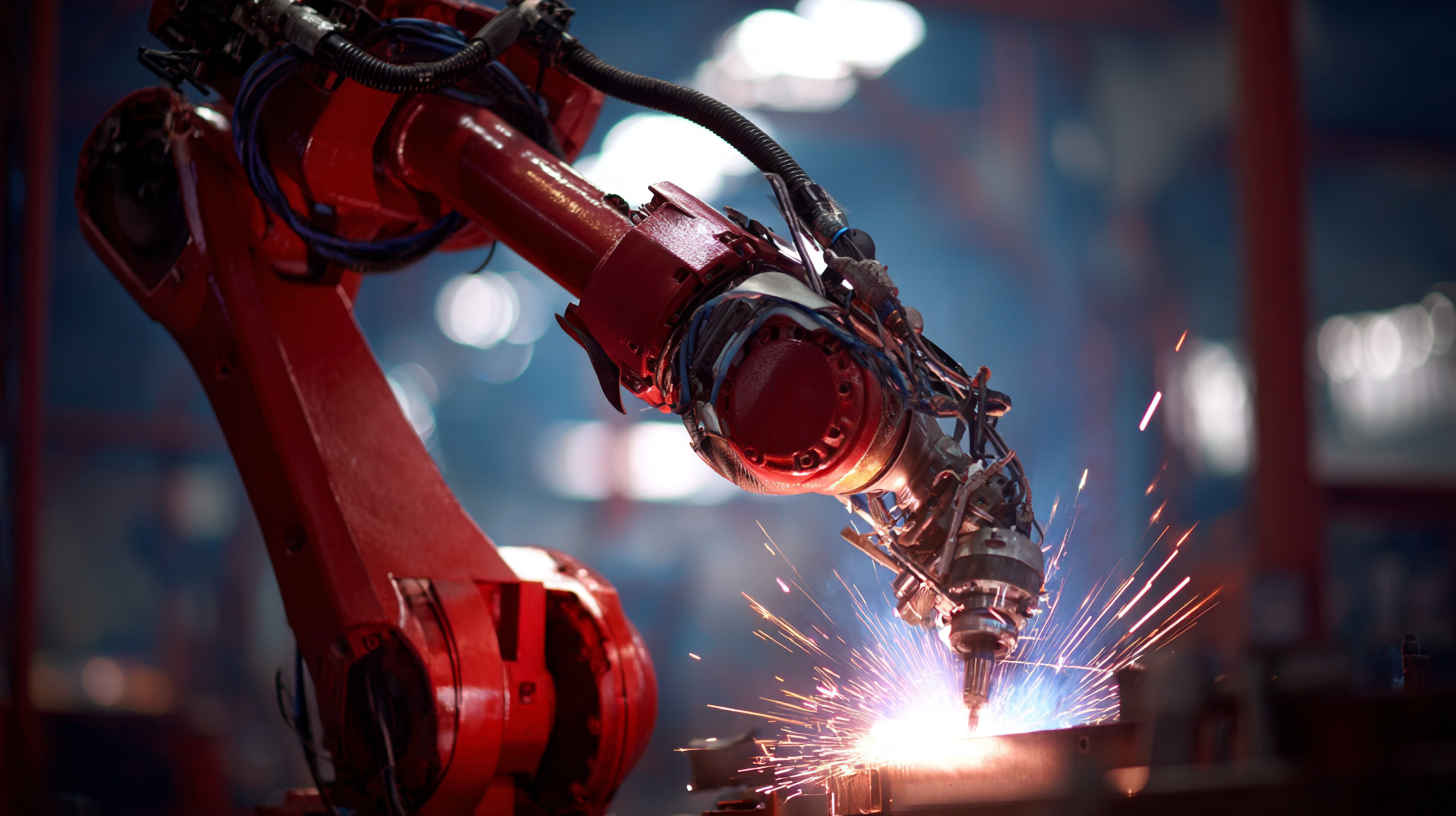

As we move further into the 21st century, the landscape of manufacturing is experiencing a significant transformation, primarily driven by advancements in automation and robotics. Among these technological innovations, the Welding Robot has emerged as a game-changer, setting new industry standards and revolutionizing traditional manufacturing processes. This advanced technology not only enhances productivity but also improves precision and safety in welding operations, making it an essential aspect of modern manufacturing strategies.

The integration of Welding Robots into production lines offers numerous advantages, including cost reduction, consistent quality, and the ability to handle complex welds that would be challenging for human operators. As industries strive to meet increasing demands for efficiency and excellence, the role of Welding Robots becomes increasingly pivotal. This article aims to explore the top ten ways Welding Robots are redefining industry standards, showcasing their capabilities and the substantial impact they have on shaping the future of manufacturing.

In understanding the transformative power of Welding Robots, it is clear that they are not just a passing trend but a fundamental shift in how manufacturing will be approached in the years to come. By analyzing their contributions and potential, we can better comprehend the trajectory of the manufacturing sector in an era characterized by rapid technological advancement.

The rise of welding robots in modern manufacturing is transforming the landscape of industrial production, driven by significant advancements in technology. As the global artificial intelligence robots market is forecasted to grow from $6.19 billion in 2025 to an impressive $32.26 billion by 2034, it reflects the increased adoption of automation across various sectors, including welding. This phase of evolution aligns with the projected growth of the arc welding equipment market, which is estimated to expand from $14.56 billion in 2024 to $22.49 billion by 2033. Such data underscores the pivotal role welding robots play in streamlining processes and enhancing productivity in manufacturing environments.

Furthermore, the integration of robotics and AI is not merely a trend but a strategic shift toward greater efficiency and sustainability. A report on automation in electronic manufacturing services (EMS) highlights how advanced technologies like robotics can significantly enhance operational efficiency. The ongoing development of intelligent robotics facilitates improved precision in tasks, thereby optimizing production workflows. As these innovative systems gain traction, the industrial sector is poised to harness the full potential of robotics, setting new standards in manufacturing excellence.

| Dimension | Value |

|---|---|

| Annual Growth Rate (%) | 15.2% |

| Market Size (USD Billion) | 4.5 |

| Percentage of Automated Welding Processes (%) | 30% |

| Average Wage Savings per Worker (USD) | 20,000 |

| Reduction in Production Time (%) | 25% |

| Projected Number of Welding Robots (Thousands) | 100 |

| Industry Adoption Rate (%) | 45% |

The integration of welding robots into manufacturing processes has revolutionized efficiency and precision in production. Unlike traditional welding methods, robotic systems operate with exceptional speed, significantly reducing cycle times. These machines can perform repetitive tasks consistently without fatigue, enabling manufacturers to increase output while maintaining high-quality standards. This leap in productivity not only optimizes resource allocation but also lowers operational costs, making businesses more competitive in the global marketplace.

Moreover, the precision offered by welding robots is unparalleled. Advanced programming and real-time monitoring capabilities allow for meticulous control over welding parameters, resulting in stronger and more reliable joints. With reduced human error, companies experience fewer defects and higher product integrity, which is critical in industries where safety and durability are paramount. As manufacturers embrace this technology, they can meet the growing demands of customers while adhering to stringent industry standards, positioning themselves at the forefront of innovation in the manufacturing landscape.

The integration of welding robots in manufacturing is not only transforming production efficiency but also significantly altering workforce dynamics. According to a report by MarketsandMarkets, the global welding robot market is projected to reach $7.6 billion by 2026, indicating a robust growth that reflects the pivotal role these machines play in modern manufacturing. As industries increasingly automate, the demand for skilled operators who can oversee and maintain these advanced systems becomes imperative.

The shift toward robotics in welding necessitates a reevaluation of the skills required in the workforce. A study by the International Federation of Robotics notes that while automation can enhance productivity by up to 30%, it also generates a skills gap as traditional welding jobs evolve. Workers need to acquire programming and operating skills for robotic systems, pushing educational institutions and training programs to adapt their curricula. This trend highlights a critical need for collaboration between manufacturers and educational sectors to ensure that the workforce is adequately prepared for the high-tech demands of the future.

The landscape of manufacturing is undergoing a significant transformation, driven by innovative technologies in welding automation. According to a report from Mordor Intelligence, the global welding automation market is projected to reach USD 7.3 billion by 2026, growing at a CAGR of 6.1% from 2021. This surge is largely attributed to the increasing demand for high-quality production processes, where welding robots are setting new standards for precision and efficiency.

Advancements in artificial intelligence and machine learning are revolutionizing the capabilities of welding robots. These systems can now perform complex tasks with a level of accuracy that was previously unattainable, reducing material waste and rework costs. Furthermore, the integration of IoT (Internet of Things) in welding automation allows manufacturers to monitor processes in real-time, leading to improved operational efficiency and maintenance scheduling. A study from the International Federation of Robotics highlights that automating welding processes can yield significant cost savings, with some companies reporting reductions in labor costs by up to 30%.

As the manufacturing sector embraces these advanced welding technologies, businesses are not only enhancing their productivity but are also improving workplace safety. The automation of welding processes minimizes human exposure to hazardous environments, aligning with the industry's ongoing commitment to worker safety. These innovative technologies are paving the way for a future where manufacturing is smarter, safer, and more efficient, ultimately redefining industry standards.

The integration of welding robots across various industries is transforming manufacturing standards, showcasing significant improvements in productivity and precision. A study by the International Federation of Robotics reported that the adoption of industrial robots, including welding applications, has increased globally by 13% year-over-year. This growth indicates a strong trend in automating welding processes to enhance operational efficiency. A notable case is the automotive sector, where manufacturers like Toyota have successfully implemented robotic welding systems that reduced labor costs by 20% while increasing output quality.

In the construction industry, the use of welding robots has led to remarkable advancements in building methodologies. For instance, a recent report from McKinsey & Company highlighted that automation in construction could lead to efficiency gains of up to 30%. Companies like Bechtel have adopted robotic welding solutions to tackle complex projects with greater accuracy and speed, thereby minimizing material waste and enhancing safety on site. These case studies illustrate how welding robots are not only redefining industry standards but also paving the way for more innovative and sustainable manufacturing practices.