Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

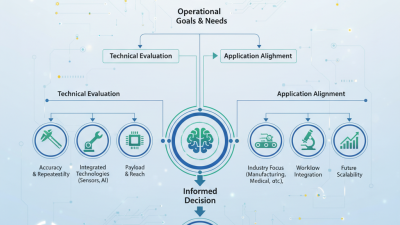

The rise of automation in various industries has ushered in the era of High Precision Robots. According to a recent report by MarketsandMarkets, the global market for high precision robotics is projected to reach $22 billion by 2028. This rapid growth highlights the increasing demand for precision and efficiency in manufacturing, electronics, and medical fields.

Dr. Emma Chen, a leading expert in robotics, emphasizes the significance of this technology, stating, “High Precision Robots are revolutionizing how we approach complex manufacturing tasks.” These robots excel in tasks requiring intricate movements and exact measurements. They improve consistency and reduce waste, ultimately enhancing productivity.

However, integrating High Precision Robots is not without its challenges. Companies must consider training workers to collaborate with these machines. As industries strive for greater efficiency, a balanced focus on human skills and robotic capabilities is essential. The path ahead is filled with potential, but reflection on current practices is crucial for sustained success.

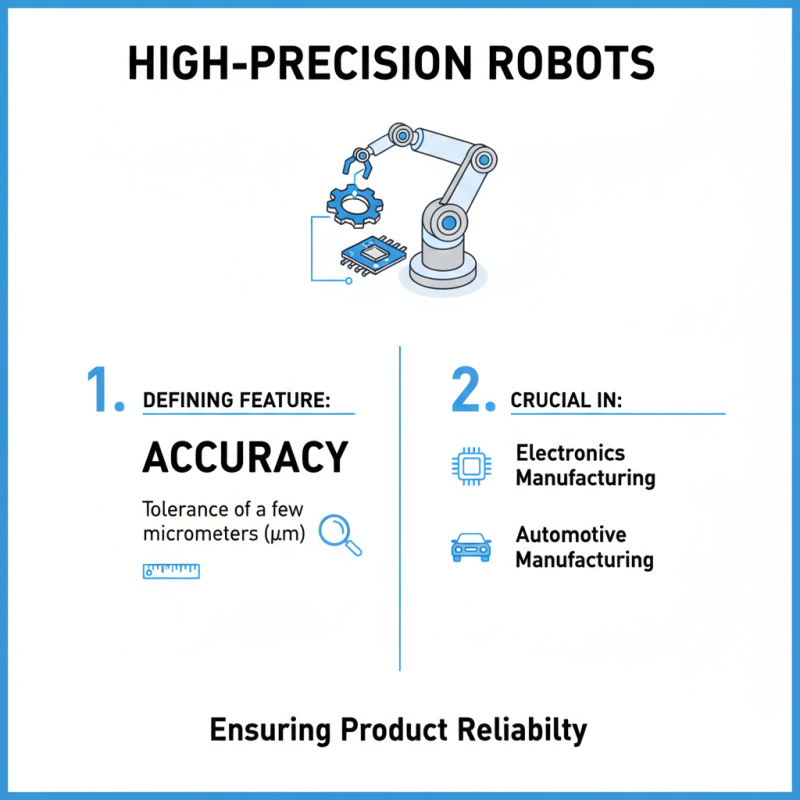

High precision robots are crucial in many industrial applications. Their defining feature is accuracy. These robots can perform tasks with a tolerance of just a few micrometers. This is necessary in fields such as electronics and automotive manufacturing. Assembly tasks often require tight tolerances to ensure product reliability.

In practice, achieving this precision can be challenging. Factors like mechanical wear and environmental conditions can impact performance. Robots must be regularly calibrated to maintain accuracy. Incorporating sensors can help monitor and adjust their operations in real time. However, this adds complexity and can sometimes lead to unexpected errors.

The programming of these robots also requires attention. Even minor coding mistakes can lead to significant production issues. Training operators to manage these systems effectively is essential. Skilled operators can identify potential problems early. Continuous improvement and adaptation are key elements in maximizing a robot's precision in manufacturing.

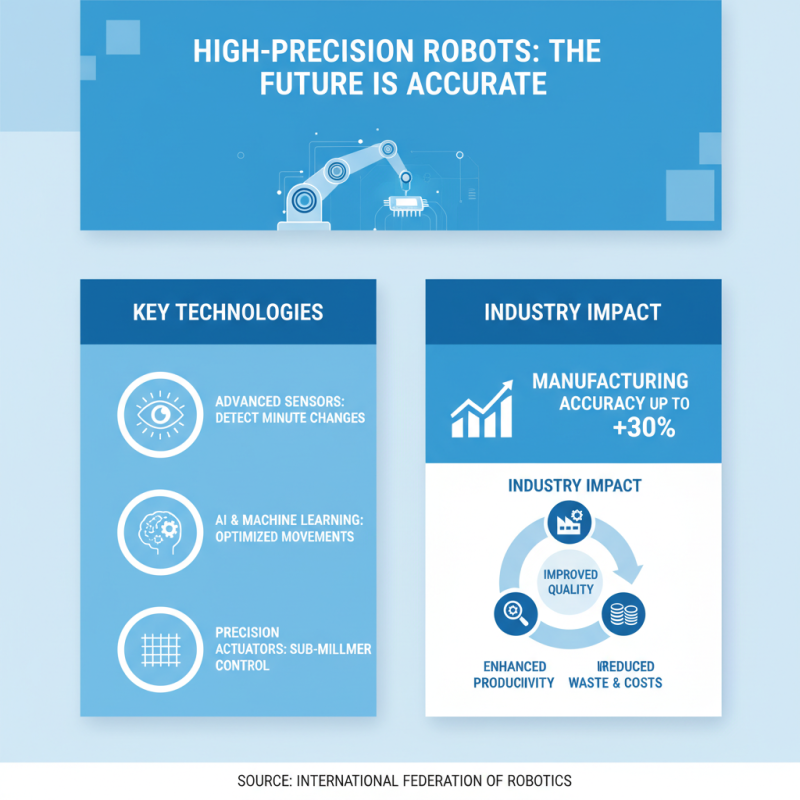

High precision robots are becoming essential in various industries. Key technologies drive this accuracy, enhancing productivity and quality. For instance, advanced sensor technology allows these robots to detect minute changes in their environment. A report from the International Federation of Robotics states that precision robots can improve manufacturing accuracy by up to 30%.

Another critical factor is machine learning. Through deep learning algorithms, robots learn from vast amounts of data. This ability to adapt improves their precision over time. For example, robots equipped with AI can analyze thousands of images to recognize and classify objects accurately.

**Tip:** Incorporating precise encoders can significantly enhance motion control. These devices measure position with high accuracy, essential for tasks requiring exact movements.

Despite advancements, challenges remain. Achieving high precision consistently can be tricky. Calibration and environmental factors impact performance. Regular maintenance is necessary to address these issues.

**Tip:** Always monitor the robot's performance metrics. This practice helps to identify deviations early. Addressing these issues promptly can prevent costly downtime.

High precision robots rely heavily on advanced sensors for their operation. These sensors provide vital feedback, allowing robots to navigate complex environments. They improve accuracy in tasks like assembly, where even a slight error can have significant repercussions. The precision of these robots can be affected by environmental factors, leading to potential challenges.

Tips: Ensure your sensor placement is optimal. Poor positioning can result in inaccurate readings.

Incorporating various types of sensors is crucial. For instance, vision systems can detect shapes and colors. Proximity sensors help robots to avoid obstacles. This redundancy is essential, yet it complicates programming. Developers often struggle to balance sensor inputs and processing times. It’s a continuous learning process.

Tips: Regularly update your algorithms to enhance robot responsiveness. This can mitigate issues related to sensor overload.

Despite technological advancements, no system is perfect. Limitations exist in sensor capabilities and processing power. Calibration also plays a role. Mistakes occur, and these can cause errors in execution. Feedback loops are critical for learning and improvement. An iterative approach can lead to breakthroughs, but one must acknowledge setbacks along the way.

Precision robotics is governed by industry standards that define performance and reliability.

Accuracy metrics are critical in assessing how well a robot can perform tasks. One common metric is positional accuracy, measuring how close a robot's end effector gets to a desired position.

An ideal robot should achieve a precision rate of ±0.1 mm or better. However, achieving this level of precision can be challenging.

Another important measurement is repeatability. This indicates how consistently a robot can return to a specified point.

It's common for robotics systems to demonstrate repeatability down to ±0.02 mm. Yet, various factors like environmental changes can impact these metrics. Robots may struggle with vibrations or thermal fluctuations, which can lead to discrepancies in accuracy.

Understanding these standards is crucial for engineers.

They must ensure that robots can meet or exceed these expectations. However, perfection is often elusive.

Manufacturers strive for the ideal, but variability in materials and assembly can introduce flaws. Continuous improvement is essential in this ever-evolving field.

High precision robots are transforming various sectors, particularly manufacturing. In 2020, the global industrial robot market was valued at approximately $43.8 billion. This figure is projected to reach nearly $70 billion by 2027, driven by a rise in automation demands. These robots excel in tasks requiring exact movements and consistency, which many traditional machines cannot achieve.

In automotive manufacturing, high precision robots assemble components with incredible accuracy. They can work at speeds up to 2 meters per second. This capability significantly reduces errors and waste. However, the initial investment can be high. Smaller manufacturers may find it challenging to adopt these technologies, creating a gap in innovation. The risk of over-reliance on these systems is also worth contemplating.

Beyond manufacturing, industries like healthcare and electronics benefit from high precision robots. In surgical applications, robots assist with delicate procedures, thereby increasing success rates. Yet, there are concerns about patient safety and technical failures. Balancing technological advancements with ethical considerations remains a critical discussion point.