Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

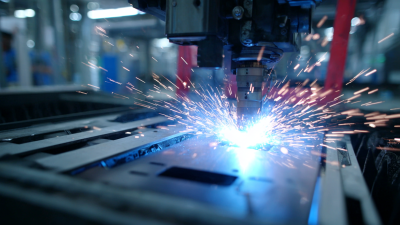

In today’s fast-paced manufacturing environment, the efficiency and precision of processes are paramount, which is where Automatic Welding Equipment plays a crucial role. According to industry expert Dr. Emily Carter, a renowned authority in welding technology, "Investing in automatic welding not only enhances productivity but also significantly reduces the potential for human error." This assertion highlights the fundamental advantage of integrating automatic welding solutions into business operations.

The adoption of Automatic Welding Equipment offers numerous benefits, from improved weld quality to faster production times. Businesses leveraging these advanced technologies can streamline their operations, ensuring they stay competitive in an ever-evolving market. Furthermore, as the demand for high-quality welds continues to escalate, the importance of automation becomes increasingly apparent, driving a shift towards these innovative solutions.

As companies seek to maximize their investment and growth potential, understanding the advantages of Automatic Welding Equipment is essential. Embracing these technologies not only fosters operational excellence but also positions businesses for long-term success in a challenging economic landscape.

Investing in automatic welding equipment can significantly enhance operational efficiency within manufacturing and construction processes. One of the primary benefits is the increased speed and consistency of welds. Automatic welding systems can operate at a higher rate than manual welding, resulting in faster production times. This not only meets tighter deadlines but also increases overall output, allowing businesses to take on more projects simultaneously.

Moreover, the precision offered by automatic welding equipment leads to improved quality in finished products. Such systems minimize human error and ensure uniform welds, which can reduce the need for extensive rework or repairs. This consistency in quality translates to higher customer satisfaction, as clients receive products that meet stringent specifications. Ultimately, the transition to automatic welding not only streamlines workflows but also establishes a stronger market reputation for reliability and excellence in craftsmanship.

When considering the cost analysis of automatic welding equipment, the initial investment may appear daunting. However, businesses must weigh this upfront cost against the potential long-term savings generated by enhanced efficiency and productivity. Automatic welding systems can significantly reduce labor costs by minimizing the need for manual labor, allowing skilled workers to focus on more complex tasks that require human oversight. This shift not only optimizes the workforce but also leads to precision in welding operations, resulting in a decrease in material waste and rework expenses.

Moreover, the longevity and durability of automatic welding equipment contribute to decreased maintenance costs over time. High-performance machines typically require less frequent repairs and can handle extended workloads without degrading in quality. This reliability means that organizations can expect a return on their investment through increased output and reduced downtime. When expanded over multiple projects and years, the financial benefits of investing in automatic welding technology outweigh the initial capital, positioning the business for sustained growth in a competitive market.

| Cost Item | Initial Investment ($) | Annual Maintenance ($) | Average Annual Savings ($) | Break-even Point (Years) |

|---|---|---|---|---|

| Automatic Welding Machine | 25,000 | 1,500 | 12,000 | 1.08 |

| Robotic Welding System | 50,000 | 2,500 | 25,000 | 1.00 |

| Semi-Automatic Welding Equipment | 15,000 | 800 | 5,000 | 2.00 |

| Traditional Welding Equipment | 10,000 | 600 | 2,000 | 4.00 |

Automating welding processes significantly enhances product quality by minimizing human error and ensuring consistency in production. Traditional welding techniques often rely heavily on the skill and experience of the welder, which can lead to variability in the finished product. In contrast, automatic welding equipment employs advanced technology and precise programming to execute uniform welds repeatedly. This precision drastically reduces the likelihood of defects, leading to fewer returns and greater customer satisfaction.

Moreover, automated welding systems are equipped with sensors and monitoring devices that can detect inconsistencies in real-time. This capability allows for immediate adjustments, further preventing defects before they escalate into larger issues. With a focus on quality control, businesses can achieve a higher standard of production, resulting in stronger, more durable products. The adoption of automation in welding not only improves the integrity of each item but also enhances the overall efficiency of the manufacturing process, paving the way for increased profitability and market competitiveness.

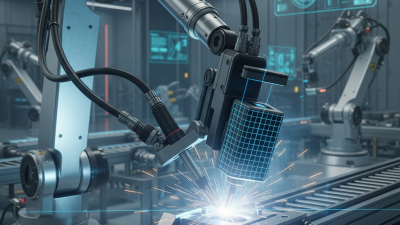

The welding industry is experiencing significant growth, driven largely by the increasing demand for automated welding solutions across various sectors. According to a report by MarketsandMarkets, the global automated welding market is projected to reach approximately $10.3 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.5% from 2021 to 2026. This surge in demand is primarily fueled by advancements in technology, the need for higher productivity, and the ongoing labor shortages that many industries face.

Automated welding not only enhances efficiency but also ensures consistent quality, which is crucial for industries such as automotive and aerospace where precision is paramount. A report from Grand View Research indicates that the adoption of robotic welding systems can decrease production times by 25% to 50%, while also reducing waste and improving the working conditions for employees. Additionally, as manufacturers increasingly focus on lean production methodologies, the integration of automated welding systems becomes essential to streamline processes and maintain competitive advantages in the market.

Furthermore, the push for sustainability in manufacturing is also contributing to the rise in automated welding solutions. Automated systems can minimize energy consumption and improve resource utilization, aligning with the industry's shift towards environmentally friendly practices. As regulations become stricter and consumers demand greener products, investing in automated welding equipment not only positions businesses to meet these market needs but also fosters long-term sustainability and profitability.

In the realm of modern manufacturing, the choice between manual and automatic welding equipment is critical in determining operational efficiency and product quality. A recent study by the American Welding Society indicates that businesses utilizing automatic welding methods report a 30% increase in productivity compared to their manual counterparts. This surge in efficiency allows manufacturers to meet growing production demands without compromising on precision or quality.

One of the most compelling advantages of automatic welding is the consistency it offers. Automated systems are designed to execute welding tasks with minimal variations, ensuring uniformity in products. According to a report from the International Institute of Welding, this consistency can reduce rework and scrap rates by up to 40%, which directly impacts the bottom line by saving costs associated with material waste and labor.

Tips: When considering investing in automatic welding equipment, evaluate your production volume and the complexity of your welding tasks. Additionally, assess the training needs for your workforce, as effective operation of automated systems may require upskilling. Embracing automation not only positions your business to thrive in a competitive market but also equips you with the technology to innovate and improve safety standards in your workspace.