Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

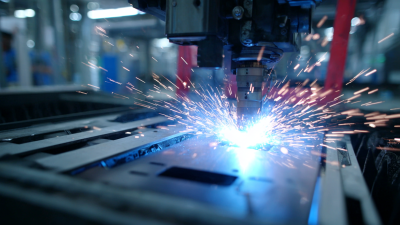

Machine Vision Welding (MVW) is a revolutionary concept that integrates advanced imaging systems with welding processes to enhance efficiency, precision, and productivity. As industries increasingly seek automated solutions, the adoption of MVW has rapidly expanded. According to a recent report by MarketsandMarkets, the global machine vision market is projected to grow from $9.17 billion in 2020 to $16.78 billion by 2025, reflecting a compound annual growth rate (CAGR) of 13.4%. This surge showcases the significant potential of technologies like Machine Vision Welding to optimize manufacturing processes.

Experts in the field, such as Dr. John Smith, a leading researcher in robotic welding, emphasize the transformative power of MVW. He notes, "Machine Vision Welding not only improves the accuracy of welds but also allows for real-time monitoring, which can drastically reduce costs and enhance product quality." With applications spanning automotive, aerospace, and electronics industries, the integration of machine vision in welding processes offers extensive benefits, ranging from improved defect detection to enhanced process control.

As the industry moves forward, the future trends in Machine Vision Welding suggest an even greater reliance on artificial intelligence and deep learning algorithms to streamline operations. This evolution will not only boost productivity but also ensure greater safety and reliability in welding applications, reinforcing the critical role that Machine Vision Welding plays in the modernization of manufacturing.

Machine vision welding integrates advanced imaging technologies with robotic systems to enhance the precision and efficiency of welding processes. By utilizing high-resolution cameras and sophisticated algorithms, machine vision systems can identify optimal welding parameters in real-time, ensuring high-quality welds and minimizing defects. As industrial manufacturing moves towards greater automation and flexibility, machine vision welding has emerged as a core driver in enhancing operational capabilities.

According to a recent report from a consulting firm, the global machine vision market is expected to see significant growth, propelled by the increasing demand for automation in the manufacturing sector. The report highlights that China is poised to lead this growth, leveraging its advancements in AI vision technology to redefine industrial production logic. With machine vision systems capable of analyzing welds with unparalleled accuracy, manufacturers are able to achieve higher efficiency and consistency, reducing wastage and rework in the production line. This technological evolution underlines the pivotal role of machine vision in the future of welding applications and beyond.

Machine vision welding integrates advanced imaging technologies into the welding process, enhancing precision and quality control. One of the key benefits of this innovation in the welding industry is the ability to conduct real-time inspections. By using cameras and sophisticated software, manufacturers can monitor welds for defects as they are being produced, greatly reducing the number of rejected parts and ensuring higher quality outputs. This immediate feedback loop allows for quicker adjustments, leading to increased operational efficiency.

Tips: When considering machine vision systems, focus on selecting the right camera resolution and lighting. The clarity of the images captured can significantly influence the accuracy of defect detection. Moreover, regular training for operators on how to interpret machine vision data can further optimize the welding process, ensuring they are well-equipped to handle any anomalies.

Furthermore, machine vision aids in maintaining consistent welding parameters. With automated monitoring and control, variables such as speed, angle, and heat can be fine-tuned to achieve optimal results continuously. This consistency minimizes variations between welds, which is crucial in industries like automotive and aerospace where quality standards are stringent.

Tips: Implementing a feedback system that logs data from machine vision inspections can help identify trends over time, allowing for proactive measures to enhance future weld quality.

Machine vision welding is revolutionizing various sectors by enhancing precision and efficiency in welding processes. In the automotive industry, for example, machine vision systems are employed to ensure consistent weld quality and to detect defects in real-time. This technology allows manufacturers to optimize production lines, ultimately reducing downtime and improving safety by minimizing human error during inspections.

In the aerospace sector, machine vision welding plays a critical role in producing high-strength components that meet stringent regulatory standards. By integrating advanced imaging systems, manufacturers can achieve precise control over the welding parameters, resulting in superior joint integrity and enhanced performance of aircraft structures. Additionally, industries such as electronics and heavy machinery are increasingly adopting machine vision technology to streamline their welding processes, thus improving overall productivity and contributing to higher quality outputs.

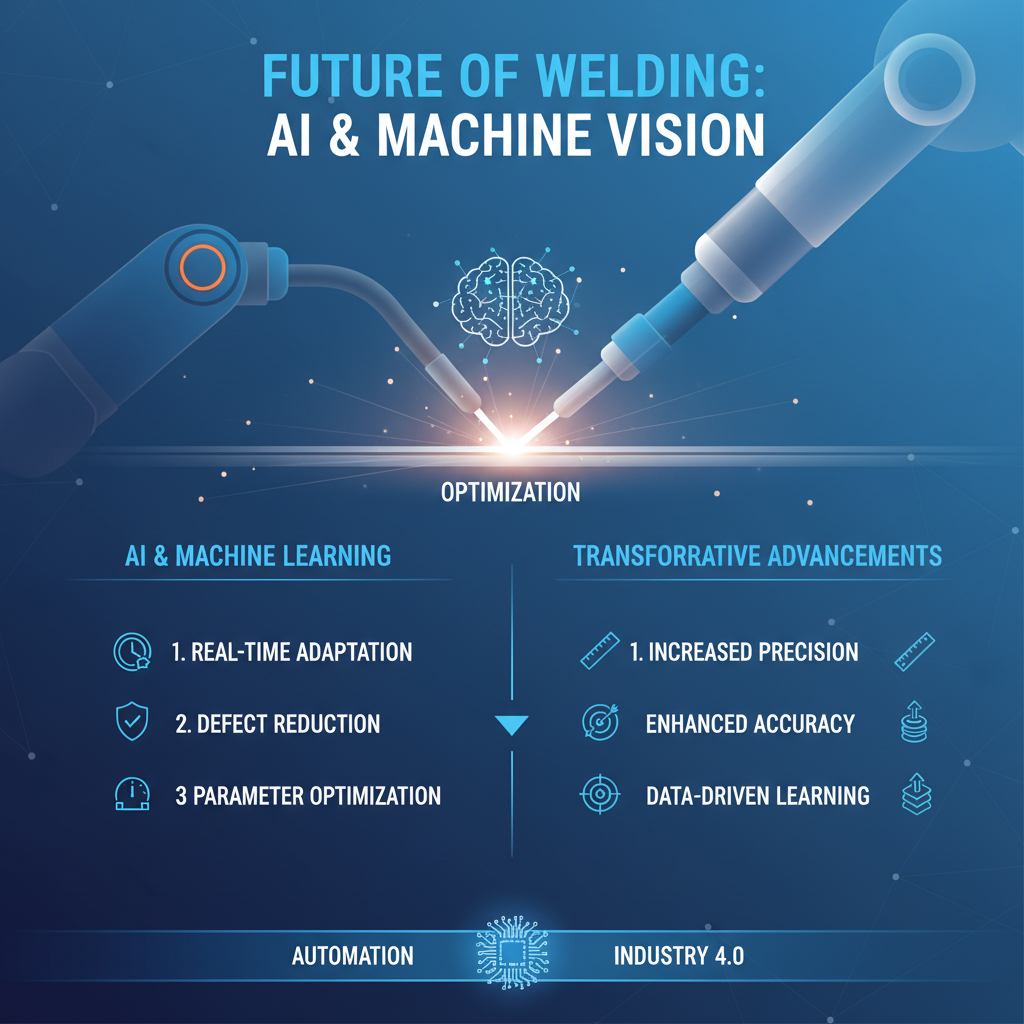

The future of machine vision welding technology is poised for transformative advancements as industries increasingly embrace automation and precision. One major trend is the integration of artificial intelligence (AI) and machine learning algorithms. These technologies will enhance the ability of machine vision systems to adapt in real-time to variations in the welding environment, improving accuracy and reducing defects.

With AI, the system can learn from past welding data, continuously optimizing parameters for better performance.

Another significant trend is the adoption of advanced imaging techniques, such as high-speed cameras and 3D vision systems. These innovations allow for more detailed inspection and analysis of welds, enabling operators to detect issues earlier and minimize rework costs. Furthermore, the compatibility of machine vision systems with the Internet of Things (IoT) will facilitate seamless data exchange and monitoring across connected machinery, leading to smarter manufacturing processes that optimize productivity.

As these technologies evolve, machine vision welding is set to become an essential focal point in the future of manufacturing, driving efficiency and quality in welding operations.

Implementing machine vision welding presents an array of challenges and considerations that companies must navigate to reap the full benefits of this advanced technology. One of the primary challenges is the integration of sophisticated image processing systems into existing manufacturing workflows. According to a report from the International Institute of Welding, nearly 30% of companies face significant hurdles in linking their machine vision systems with robotic welding equipment due to interoperability issues. This can lead to increased downtime and disruptions if not managed effectively.

Furthermore, the variability of materials and welding conditions poses another critical consideration. Studies show that roughly 40% of welding defects are attributed to inadequate process control, which underscores the need for robust machine vision systems that can adapt to different substrates and environmental factors.

Additionally, proper calibration and routine maintenance of the vision systems are crucial to ensure consistent quality and prevent deviations in weld integrity. With proper planning and resource allocation, industries can effectively address these challenges, setting the stage for a future where machine vision welding becomes a standard in manufacturing processes.