Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In recent years, the manufacturing sector has increasingly embraced automation to enhance productivity and precision. One of the most significant advancements in this area is the integration of Machine Vision Welding (MVW) technology, which leverages advanced imaging systems for real-time quality control and process optimization. According to a report by MarketsandMarkets, the global machine vision market is projected to reach over $12 billion by 2025, evidencing the growing importance of automated inspection systems in various industries, including automotive, electronics, and aerospace.

Machine Vision Welding allows for improved accuracy in welding processes by utilizing high-resolution cameras and complex algorithms to guide the welding equipment. This technology not only enhances the precision of welds but also significantly reduces the likelihood of defects, which can result in costly rework or failure. A study conducted by the International Journal of Advanced Manufacturing Technology highlights that implementing MVW can increase operational efficiency by up to 30%, underlining the importance of adopting such innovations in competitive manufacturing environments.

As industries strive for higher standards of quality and efficiency, optimizing Machine Vision Welding becomes essential. By focusing on enhancing the capabilities of MVW systems, manufacturers can reduce production time, minimize material wastage, and ensure consistent weld integrity. This paper explores various strategies and practices that can help in achieving these goals, ultimately leading to a more effective and precise welding process.

Machine vision systems have revolutionized the welding industry by enhancing precision and efficiency in various welding processes. This advanced technology utilizes cameras and image processing to monitor and control welding operations dynamically. By enabling real-time feedback, machine vision helps operators to identify defects and make necessary adjustments immediately, resulting in higher quality welds and reduced material waste.

Tips: Implementing machine vision requires thorough calibration of the system to align with the specific requirements of your welding operation. Regularly check and maintain the cameras and lighting systems to ensure optimal performance. Additionally, consider integrating machine learning algorithms to enhance the system's ability to detect anomalies and improve precision over time.

Furthermore, understanding the characteristics of the materials and the specific welding techniques used in your processes is crucial. Different materials may reflect light differently, which can impact the machine vision system's effectiveness. By tailoring the vision system parameters to accommodate these factors, operators can maximize the efficiency and reliability of the welding process.

Tips: Engage with your team in continuous training on machine vision technology to adapt to changing welding applications. Ensure that your operators are well-versed in interpreting the data provided by the system, which will ultimately lead to more informed decision-making and improved welding outcomes.

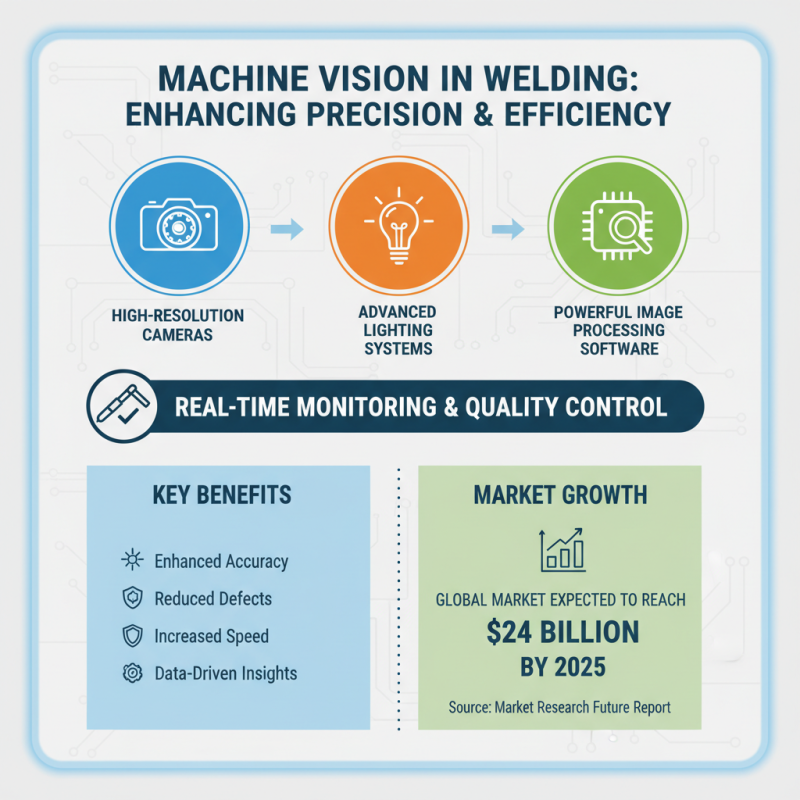

Machine vision systems play a critical role in enhancing precision and efficiency in welding applications. By integrating advanced imaging technologies, these systems facilitate real-time monitoring and quality control throughout the welding process. Key components that contribute to the effectiveness of machine vision in welding include high-resolution cameras, lighting systems, and powerful image processing software. According to a report from the Market Research Future, the machine vision market is expected to reach $24 billion by 2025, highlighting the growing recognition of its importance in industrial automation.

High-resolution cameras are essential for capturing detailed images of welds, enabling operators to detect both surface and subsurface defects. Coupled with appropriate lighting systems, which can include structured or laser lighting to enhance feature visibility, these cameras ensure that the weld quality can be assessed with high fidelity. Furthermore, image processing software utilizing artificial intelligence and machine learning algorithms can analyze the captured images to provide insights into weld integrity and process efficiency. A study published in the Journal of Manufacturing Science and Engineering revealed that incorporating machine vision can increase welding process efficiency by up to 30%, underscoring its pivotal role in modern manufacturing environments.

Machine vision has significantly transformed the landscape of welding by enhancing precision and efficiency through a combination of advanced imaging technology and real-time data analysis. To achieve superior results, it is essential to implement specific techniques that focus on enhancing welding accuracy. For instance, employing high-resolution cameras can capture intricate joint details, allowing for better alignment and resulting in fewer defects. Utilizing machine learning algorithms helps in analyzing visual data for consistent weld quality, enabling automatic adjustments to be made on the fly to tackle variations in materials and environments.

Tips for Enhancing Precision in Welding with Machine Vision:

Optimizing machine vision welding involves implementing strategic approaches that enhance both precision and efficiency in the welding process. One effective strategy is the integration of advanced algorithms that improve image processing capabilities. These algorithms can facilitate real-time analysis of weld joints, allowing for immediate adjustments based on the detected conditions. By employing techniques such as machine learning and artificial intelligence, the system can continuously learn from previous welds, thereby refining its performance and reducing the likelihood of defects over time.

Another critical component in enhancing efficiency is the calibration of the optical systems used in machine vision. Proper calibration ensures that the camera systems capture high-quality images with accurate color representation and depth perception. Implementing regular maintenance schedules and utilizing high-resolution cameras can significantly improve the visual input quality, leading to better decision-making by the welding system. Additionally, integrating feedback loops where the machine vision system communicates with the welding parameters can ensure that adjustments are made proactively, further increasing operational efficiency and weld consistency.

| Dimension | Current Value | Target Value | Improvement Strategy |

|---|---|---|---|

| Welding Speed (mm/s) | 50 | 70 | Optimize process parameters |

| Weld Quality (defects per 1000 welds) | 5 | 2 | Implement real-time monitoring |

| Energy Consumption (kWh) | 15 | 10 | Upgrade to energy-efficient equipment |

| Setup Time (minutes) | 120 | 60 | Standardize procedures and training |

| Maintenance Frequency (times/month) | 4 | 2 | Adopt predictive maintenance |

Case studies have shown that implementing machine vision in welding processes significantly boosts both precision and efficiency. One notable instance involves a manufacturer that integrated a machine vision system to monitor seam alignment during the welding of automotive components. By capturing real-time images and utilizing advanced algorithms to analyze these images, the system ensured that the welds were consistently aligned according to specified tolerances. This not only minimized the number of defective parts but also reduced rework, ultimately leading to substantial cost savings for the company.

Another example is a fabrication plant that employed machine vision technology to automate the inspection of weld quality. The machine vision system was designed to detect flaws such as undercutting, porosity, and inconsistent bead profiles. By replacing manual inspection with this automated solution, the plant improved its inspection speed and accuracy, allowing for quicker feedback loops in the production line. This transition not only enhanced overall product quality but also enabled the plant to increase its throughput, demonstrating the tangible benefits of machine vision in industrial welding applications.