Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

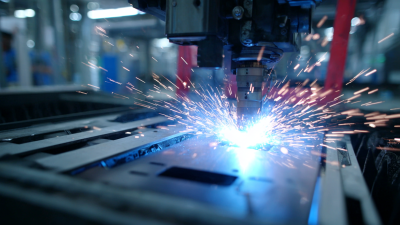

The shipbuilding industry is undergoing a significant transformation. Central to this shift is the advent of the Shipbuilding Welding Robot. These robots are changing how ships are constructed. They increase efficiency and precision in welding, which is a critical component of shipbuilding.

Shipbuilding Welding Robots perform tasks faster than human welders. They can work in tight spaces and can handle heavy materials with ease. This innovation enhances safety by reducing human errors and exposure to hazardous environments. However, this shift is not without challenges. Job displacement is a real concern for traditional welders.

The integration of technology should not solely focus on productivity. There must be a balanced approach that considers the workforce's future. It raises questions about training and job security. As the maritime industry embraces these robots, society must reflect on the implications. The future of shipbuilding may be automated, but the human element remains vital.

The shipbuilding industry faces numerous challenges, particularly in the area of traditional welding methods. Manual welding can be time-consuming and error-prone. Reports indicate that around 20% of production inefficiencies in shipbuilding stem from welding processes. This inefficiency often translates to increased labor costs and longer lead times. The unpredictability of human welders can lead to inconsistent quality, further complicating timelines and budgets.

Moreover, safety concerns loom large in this sector. In traditional shipyards, welding is deemed one of the most hazardous tasks. According to industry studies, welding-related accidents account for a significant portion of workplace injuries. Workers often face exposure to harmful fumes and high temperatures, increasing health risks. As a result, shipbuilders struggle to maintain both productivity and worker safety.

The introduction of welding robots offers a potential solution. These machines can perform precise welds consistently, reducing the risk of human error. However, integrating robotics into existing shipbuilding practices presents its own set of challenges. The initial investment can be substantial. Additionally, there is often a steep learning curve for operators. It's crucial for shipbuilders to navigate these hurdles to fully capitalize on the advantages of robotic welding.

| Dimension | Traditional Welding | Welding Robots |

|---|---|---|

| Speed | Slow, labor-intensive | Faster, automation improves throughput |

| Precision | Inconsistent | High precision, reduced defects |

| Labor Costs | Higher, skilled labor required | Lower, minimal human intervention |

| Safety | Higher risk of injuries | Reduced on-site hazards |

| Flexibility | Limited to specific tasks | Highly adaptable to various designs |

| Training Time | Long, complicated skill development | Shorter, more straightforward operation |

The emergence of welding robots in maritime shipbuilding marks a significant shift. These robots enhance precision and efficiency during construction. They can work continuously without fatigue. When programmed correctly, they produce high-quality welds. However, there can be errors in programming that lead to defects. The industry is still figuring out how to minimize these mistakes.

By automating the process, companies are also addressing labor shortages. Skilled welders are aging, and young workers are hard to find. Robots fill this gap, but their integration poses challenges. Training staff to work alongside robots is crucial. Some employees may feel threatened by this technology. Communicating the benefits is essential to fostering acceptance.

Despite these challenges, the advantages are clear. Robots can operate in environments too dangerous for humans. They can also achieve consistent results, enhancing overall safety. However, reliance on robots may reduce human oversight. Striking a balance between automation and human skill is vital for the future of shipbuilding. The journey is ongoing, with many lessons still to learn.

Robotic welding is changing shipbuilding. These machines can work continuously, enhancing efficiency significantly. With minimal downtime, they complete complex welds faster than human workers. This improved productivity allows shipyards to meet tight deadlines without sacrificing quality.

Precision is another key advantage. Robots weld with consistent accuracy, minimizing defects. They adhere to specifications perfectly, which reduces material waste. However, reliance on technology may lead to concerns about worker displacement. Still, robots handle repetitive tasks, freeing skilled workers for more complex jobs.

Cost savings stand out in the long run. Initial investments can be high, but operational costs drop. Robots use resources more effectively and reduce rework. Yet, shipyards must invest in ongoing maintenance and software updates. The balance between human skill and robotic efficiency remains an area for reflection in the industry.

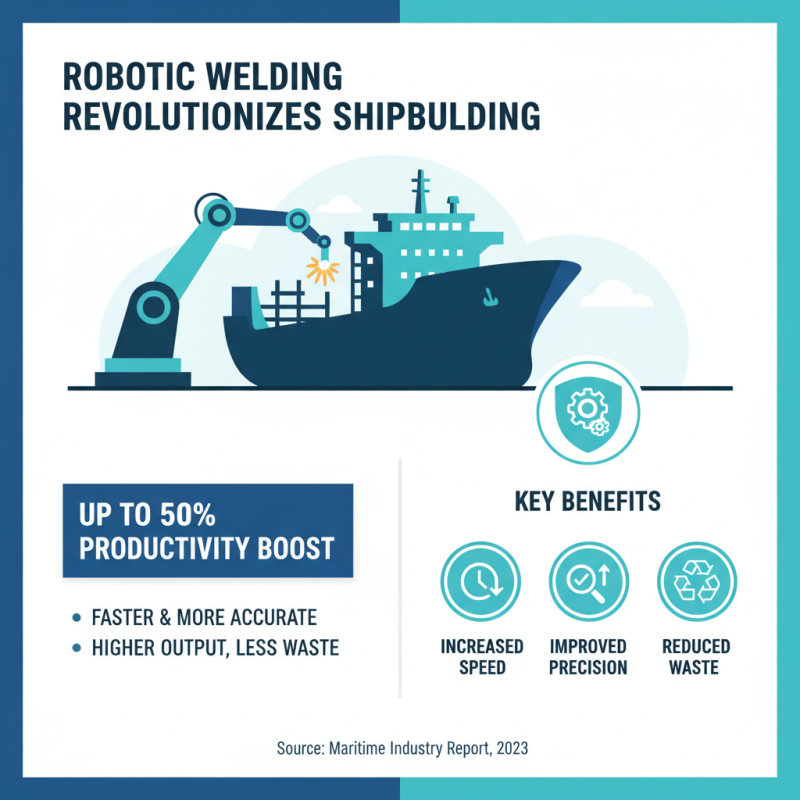

The use of welding robots in shipbuilding is transforming productivity across the maritime industry. According to recent industry statistics, companies that have adopted robotics have reported a productivity boost of up to 50%. These machines work faster and more accurately than human welders. This improvement leads to higher output and reduced waste during the manufacturing process.

However, the integration of robots is not without challenges. Training personnel to work alongside these machines is crucial. There is a learning curve that impacts initial productivity. Reports indicate that about 30% of workers feel unprepared for this shift. As businesses navigate this transition, balancing technology with human skills remains essential.

Moreover, the upfront costs of these robots can be significant. While they offer long-term savings, the initial investment can deter smaller shipbuilders. In 2022, about 60% of small to mid-sized companies reported hesitancy in adopting robotics due to financial concerns. This hesitation can slow overall industry progress. The maritime sector must address these issues to fully harness the potential of robotics.

The maritime industry is witnessing a remarkable shift due to AI and automation in welding solutions. These technologies enhance precision and speed. Welding robots, for instance, can operate in harsh environments. They complete tasks with consistent quality, reducing the chances of human error. Automation streamlines production, allowing shipbuilders to increase output and efficiency.

However, reliance on automation isn't without its challenges. The integration of AI requires skilled personnel who can manage advanced systems. Workers may worry about job displacement. Training programs must adapt to this evolving landscape, ensuring people can work alongside robotic systems. Continuous learning will be vital in navigating this change.

The future of maritime welding is promising yet complex. As technology progresses, companies must balance innovation and workforce needs. Metrics, data analysis, and feedback will guide this transformation. Embracing these trends could redefine standards in shipbuilding, but it also requires us to reflect on the human element involved.