Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

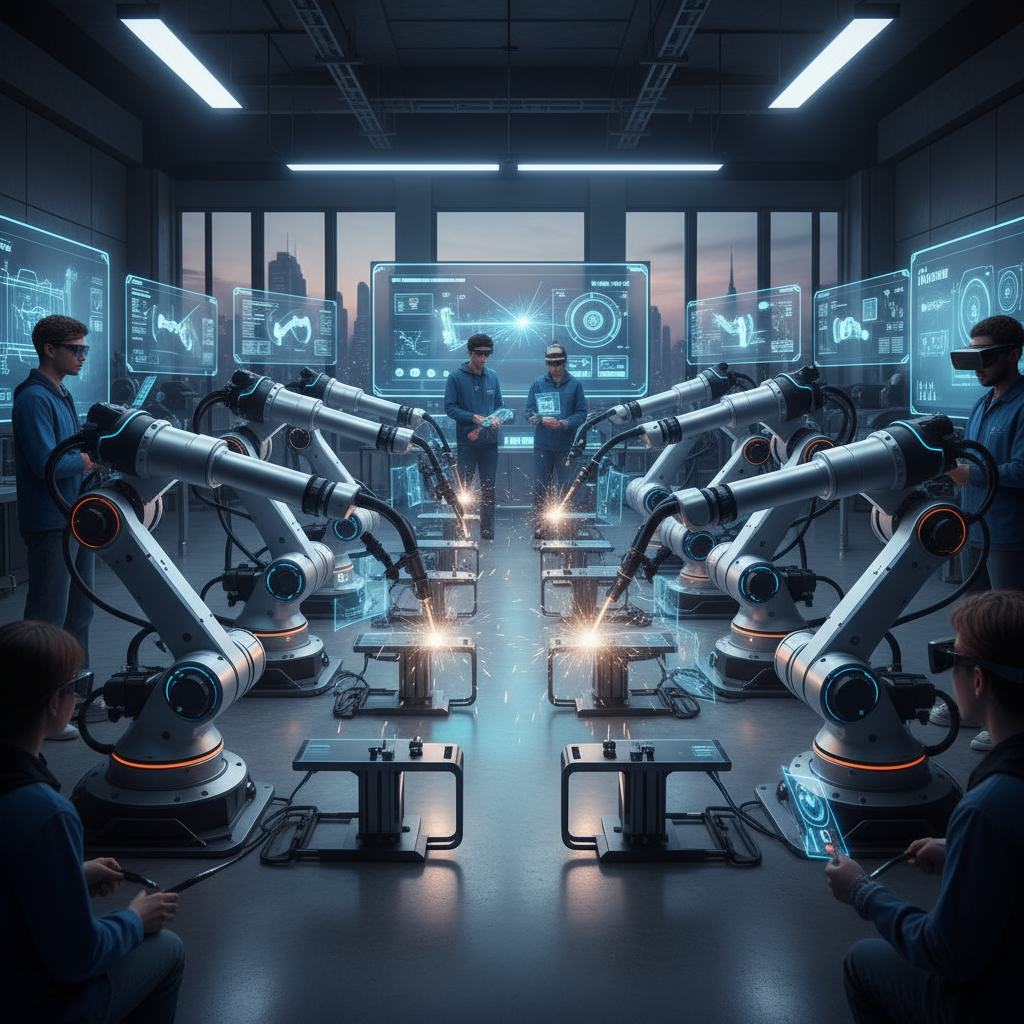

As the demand for skilled welders continues to increase, the welding education sector is evolving to meet industry needs. According to the American Welding Society, the U.S. will experience a shortage of approximately 400,000 welders by 2024, emphasizing the urgent need for effective training solutions. This has prompted educational institutions and training facilities to seek innovative technologies that can enhance the learning experience, particularly in manual and automated welding processes. Among these technologies, Teaching Welding Robots have emerged as a pivotal resource, enabling students to acquire practical skills in a safe and controlled environment.

Teaching Welding Robots not only provide hands-on experience but also help in bridging the skills gap that the welding industry faces today. A report by McKinsey suggests that automation in education can lead to a 30% increase in skill retention among students. By integrating these advanced robots into welding programs, trainees can benefit from personalized learning experiences that adapt to their pace and proficiency levels. This initiative not only prepares them for real-world challenges but also ensures they are equipped with the latest technological knowledge that is highly sought after in today's job market. As we explore the Top 10 Teaching Welding Robots of 2025, it becomes evident that these tools are crucial in shaping the future of welding education and training, providing a robust pathway towards a successful career in welding.

The welding robots of 2025 are set to transform educational environments with their innovative features designed to enhance learning experiences. These advanced machines incorporate augmented reality (AR) systems that provide real-time feedback to students as they practice welding techniques. By overlaying digital information onto the physical workspace, learners can visualize their progress and identify areas needing improvement instantly. This immersive approach not only boosts engagement but also accelerates the mastery of essential welding skills.

Moreover, the inclusion of AI-driven adaptive learning systems in these robots personalizes the educational experience for each student. By assessing individual skill levels and learning paces, the robots can tailor their instructional methods, offering customized guidance and resources. This adaptability ensures that students receive the support they need to develop their skills effectively. Additionally, the integration of remote collaboration features allows learners to connect with peers and instructors worldwide, fostering a global learning community and enhancing collaborative problem-solving in welding practices.

The integration of welding robots into technical education is revolutionizing the way students acquire essential skills. According to a recent report by the International Federation of Robotics (IFR), the use of welding robots in education can improve learning outcomes by up to 30% compared to traditional methods. These robots provide hands-on experience that enhances understanding, allowing students to see real-time results of their work and adjust according to feedback. This form of engagement not only facilitates better retention of knowledge but also prepares students for modern manufacturing environments where automation is rapidly becoming the norm.

Utilizing welding robots in classrooms also addresses the growing skills gap in the industry. The welding workforce is aging, and many institutions are struggling to attract new talent. A study from the American Welding Society reveals that by 2025, there will be a shortage of over 400,000 skilled welders. By incorporating robotic welding systems into curricula, educational institutions can better equip students with relevant skills, making them more marketable upon graduation.

**Tips:** When implementing welding robots in educational settings, ensure that instructors receive adequate training on these technologies. This empowers them to guide students effectively and handle any technical issues that arise. Additionally, consider conducting workshops or seminars involving industry professionals; this not only enhances learning but also builds connections for future employment opportunities. Ultimately, fostering an adaptive learning environment with cutting-edge technologies is key to engaging the next generation of welders.

| Robot Model | Learning Capability | Flexibility | Safety Features | Cost ($) |

|---|---|---|---|---|

| Model A | Advanced welding techniques | High adaptability for various tasks | Emergency stop, safety sensors | 10,500 |

| Model B | Interactive learning modules | Modular design for easy updates | Real-time monitoring | 12,250 |

| Model C | Basic to advanced courses | Multi-process capability | Guarding systems, alerts | 9,800 |

| Model D | Real-time feedback | Highly customizable workflows | Built-in emergency protocols | 15,300 |

| Model E | Hands-on training simulation | Flexible operation modes | Caution signs, automatic shutdown | 11,000 |

| Model F | Gamified learning experience | Dynamic task assignment | Integrated safety shields | 14,000 |

| Model G | Enhanced troubleshooting skills | Versatile technology integration | Fail-safe mechanisms | 13,500 |

| Model H | Practice on various joints | Supports multiple welding techniques | Smart sensors, alert systems | 8,750 |

| Model I | Hybrid learning approach | Quick reprogramming | Smart home integration for safety | 10,200 |

| Model J | Instructor-led sessions | User-friendly interface | Comprehensive safety checks | 12,800 |

The welding industry is experiencing a technological revolution, with advanced welding robots playing a crucial role in skill development for aspiring welders. According to a recent report by the International Federation of Robotics, the demand for welding robots is expected to grow by 20% annually, highlighting the necessity for educational institutions to integrate these machines into their training programs. In 2025, top models will offer enhanced features such as AI-driven programming and improved safety standards, making them essential tools for effective learning.

When comparing leading welding robot models, consider factors like precision, ease of use, and adaptability to various welding methods. For instance, models equipped with real-time feedback systems can help learners identify and correct mistakes instantly, fostering a better grasp of techniques. As experts highlight, immersive learning experiences provided by these robots significantly increase retention rates and skills application in practical scenarios.

Tips: To maximize the benefits of welding robots in training, educators should focus on hands-on learning experiences. Incorporating simulations and virtual reality can further enhance understanding. Additionally, maintaining up-to-date knowledge of robot advancements will ensure that programs prepare students for the evolving industry landscape.

This chart compares the performance ratings of the top 10 teaching welding robots of 2025 based on various skill development metrics such as precision, learning adaptability, ease of use, and programming flexibility.

The integration of AI and machine learning in modern welding robots marks a transformative shift in educational environments for aspiring welders. These advanced technologies enable teaching machines to adapt to individual learning styles, providing tailored instruction that can significantly enhance skills acquisition. By analyzing students' performance in real-time, AI-powered robots can identify areas for improvement, offering instant feedback to foster better understanding and proficiency.

Tips for effective learning with AI-powered welding robots include utilizing the robot's data analytics capabilities to track progress over time. Students should regularly review their performance metrics to identify trends and adjust their learning strategies accordingly. Additionally, collaborating with peers while interacting with these robots can create a richer learning experience, allowing for the exchange of techniques and ideas.

Another valuable tip is to embrace the hands-on experience offered by these robots. Students should aim to engage with the technology fully, experimenting with different welding techniques and settings. This hands-on practice, combined with the insightful feedback from the AI systems, can accelerate the mastery of essential welding skills, preparing learners for real-world applications.

The welding industry is undergoing significant changes driven by advancements in robotics and artificial intelligence. As we approach 2025, the integration of smart welding robots in vocational education promises to revolutionize skills training. These advanced machines not only enhance learning experiences but also provide students with hands-on practice in a controlled, safe environment. By incorporating automation into the curriculum, institutions are preparing students for future job markets that will increasingly demand proficiency in both welding and robotic technologies.

Furthermore, the trends in welding robotics reflect a broader shift towards digitalization and sustainability within the industry. Automation not only improves efficiency but also addresses labor shortages by enabling skilled workers to focus on more complex tasks. As educational institutions evolve alongside these technological advancements, they must embrace the potential of AI-driven robotics to better equip the future workforce. This proactive approach not only enhances the learning experience but also ensures that students are well-prepared for the changing landscape of the metal fabrication industry.