Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the industrial world, selecting the right welding and cutting machinery is crucial. According to welding expert John Smith, “The right machinery makes all the difference in efficiency.” Choosing the best equipment ensures a successful operation. It can save time and costs, making your project more profitable.

Welding and cutting machinery varies greatly in technology and application. From plasma cutters to TIG welders, each has unique features. Understanding these can be overwhelming. Many newcomers feel lost when confronted with so many options. It’s important to reflect on the specific needs of your projects.

Investing wisely in welding and cutting machinery impacts productivity. A poor choice can result in delays and increased expenses. Therefore, take time to research and consider your choices. Sometimes, it’s beneficial to consult with experts. They can guide you in avoiding common pitfalls in this complex field.

Welding and cutting machinery play a crucial role in various industries. Understanding different types of equipment is essential for making the right choice. For example, arc welding offers versatility and is popular in construction. In 2022, nearly 30% of welding processes used this method, showcasing its importance.

When selecting machinery, consider the material you will work with. Different machines are better suited for specific materials. In 2019, reports indicated that MIG welding was favored for aluminum due to its clean finish.

Tip: Assess the thickness of the material you're working with. Thicker materials may require more powerful machines for effective cutting.

Plasma cutting is another option that stands out. It is known for its speed and precision. However, it can be complex to master. Only 60% of operators feel confident with this technology.

Tip: Look into training resources for your chosen machinery. Understanding the operation can significantly improve your results.

Take into account the maintenance needs of the equipment. Some machines may require more frequent servicing. This necessity could impact downtime and efficiency.

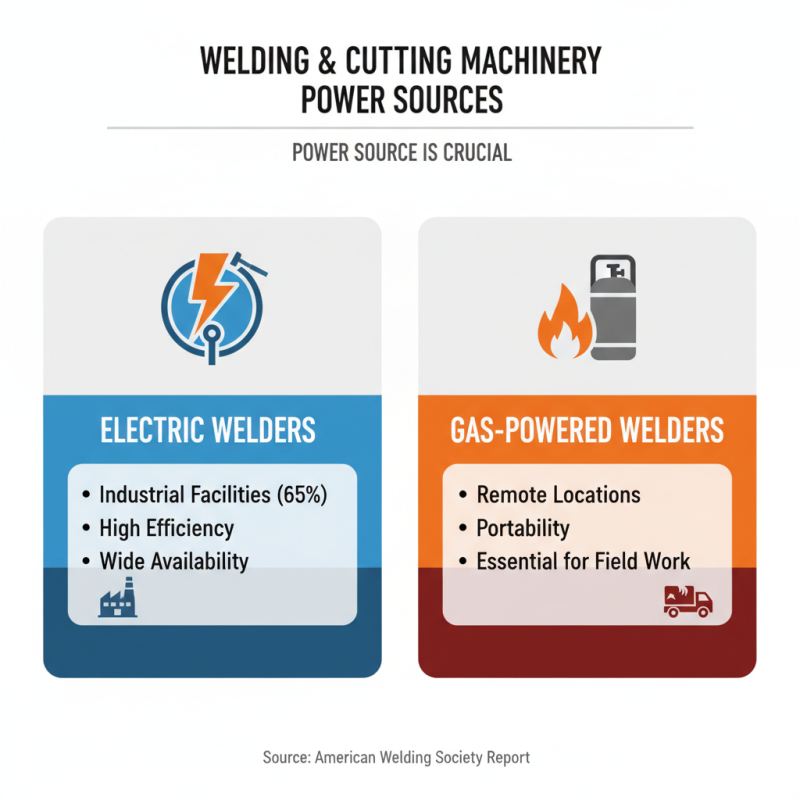

When choosing welding and cutting machinery, the power source is crucial. Different operations have unique power requirements. For instance, a report by the American Welding Society indicates that 65% of industrial facilities use electric welders. They are popular due to their efficiency and wide availability. However, gas-powered options remain essential for portability in remote locations.

Evaluating your specific needs is vital. If your projects require frequent relocation, a gas-powered welder might suit you better. In contrast, for stationary work, electric models can provide consistent output. According to industry studies, about 70% of users prefer electric because of reduced operating costs. Yet, many overlook their initial investment versus long-term savings.

It’s also important to consider energy sources when selecting machinery. High-voltage lines may not be accessible on every job site. A 2023 market analysis showed that about 15% of users faced power supply issues impacting their operations. Knowing your site’s power capacity helps avoid equipment shortages. Ultimately, aligning machinery selection with power needs ensures smoother operations.

When selecting welding and cutting machinery, safety should always come first. Assessing the safety features of equipment is crucial. Look for machinery with automatic shutoff systems. These can help prevent accidents when the machine is not in use. Check for built-in ventilation systems, ensuring that harmful fumes are safely extracted.

Evaluate the presence of protective guards. These shields can be lifesavers. They help minimize the risk of exposure to sparks and molten material. Pay attention to the machine’s electrical safety features as well. Overload protection can prevent electrical fires. It’s essential to ensure that any cutting equipment includes emergency stop mechanisms. These features can make a significant difference.

Consider also the availability of personal protective equipment (PPE). A machine might be safe, but inadequate PPE can still pose risks. Emergency procedures should be easily accessible. It's important to know what steps to take in case something goes wrong. Not every machine meets the same standards, so scrutinizing these details is essential. Being thorough in this process could save lives.

When selecting welding and cutting machinery, maintenance and support services are often overlooked. Many people focus solely on performance and price. However, machinery without proper support can lead to unexpected downtime. It's vital to consider how quickly service can be accessed when needed. A machine may work well today, but issues can arise without warning.

Support services play a crucial role in ensuring the longevity of your equipment. Regular maintenance can prevent significant breakdowns. Look for providers that offer clear service packages. Understand the response times they promise. Will a technician be on-site within hours or days? It's essential to have realistic expectations.

Reflect on the after-sales support available. Some companies may not follow through with their commitments. Imagine facing a critical breakdown with delayed responses. Maintaining a relationship with a reliable support service can provide peace of mind. In the long run, investing in good maintenance may save both time and repairs.

When selecting welding and cutting machinery, budgeting is crucial. You must balance cost and performance. Quality equipment might cost more upfront but can save money long-term. Cheaper options can lead to frequent repairs and replacements. This adds up quickly.

Consider the specific tasks you need the machinery for. Do you require precision or speed? The balance between these features impacts overall performance. Sometimes, a more expensive model might come with features you don’t need. Reflect on your operational needs thoroughly before making a decision.

Always review maintenance costs. Some machines may have lower initial costs but higher upkeep. Additionally, think about the availability of parts. This factor can influence your machinery's longevity and reliability. Not all suppliers provide the same level of service or support. Develop a clear understanding of your budget constraints. Align this with the expected performance to make an informed decision.