Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the ever-evolving landscape of industrial automation, the application of robotics in welding has emerged as a crucial component in enhancing productivity and precision. Teaching welding robots to perform complex tasks with high efficiency requires not only technical expertise but also an understanding of the nuanced behaviors of these machines. As industries strive for standards that meet the increasing demands for quality and speed, mastering the art of programming and instructing these robotic welders becomes paramount.

Effective methods for teaching welding robots involve a comprehensive approach that incorporates both software capabilities and practical training techniques. By utilizing advanced programming strategies, operators can optimize the fine motor skills and adaptability of welding robots, ensuring consistent and flawless welds. Additionally, a focus on precision in teaching these robots can lead to significant reductions in waste and rework, ultimately contributing to a more streamlined manufacturing process.

Through the exploration of best practices and innovative techniques, manufacturers can unleash the true potential of their welding robots. By embracing a systematic approach to teaching welding robots, businesses can achieve not only enhanced operational efficiency but also a transformative impact on overall production excellence.

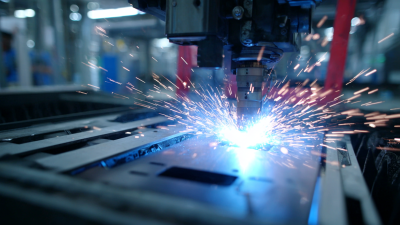

Welding robots have become an integral part of modern manufacturing processes, offering significant benefits in terms of efficiency and precision. Understanding the fundamentals of these machines is crucial for any operation looking to optimize their use. At their core, welding robots are automated systems equipped with advanced sensors and programming capabilities that enable them to perform various welding tasks. They are designed to operate in environments that require high levels of consistency and speed, making them essential for industries such as automotive, aerospace, and construction.

The applications of welding robots extend beyond traditional welding methods. They can be programmed for a variety of welding types, including MIG, TIG, and spot welding, adapting to the specific materials and geometries involved in different projects. Furthermore, their integration with other automated systems can streamline production lines, reducing labor costs and minimizing human error. By utilizing welding robots, companies can not only enhance their output quality but also improve workplace safety as these machines take over hazardous tasks, providing a safer environment for human workers. As industries continue to advance, the role of welding robots and their sophisticated capabilities will undoubtedly evolve, making it essential for teams to stay informed on best practices and efficient programming techniques.

When discussing the efficiency of welding robots, several key factors come into play that can significantly impact their operational performance. One of the primary considerations is the calibration of the robot's parameters. According to a report by the International Federation of Robotics, optimal calibration can lead to improvements in precision by up to 30%, which directly translates to less rework and material waste. Properly calibrated robots not only enhance the quality of the welds but also ensure that the operational speed is aligned with the complexity of the task at hand.

Another critical factor affecting efficiency is the choice of welding technique and the corresponding settings. For instance, studies have shown that integrating advanced welding processes, such as laser welding, can increase production rates by as much as 60% compared to traditional methods. This highlights the importance of updating welding techniques to leverage technological advancements. Furthermore, the proper programming of the welding paths can minimize unnecessary movements, thus optimizing cycle times. In a competitive market, understanding the interplay between these factors can provide manufacturers with a significant edge in productivity and cost-effectiveness.

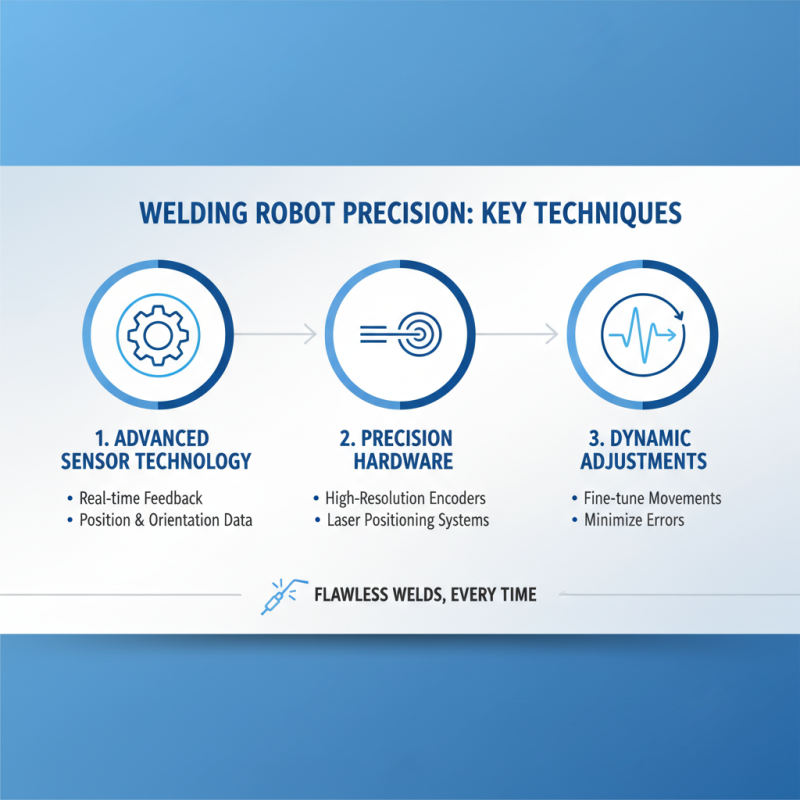

To achieve precision in movement when teaching welding robots, it is essential to focus on several core techniques that enhance their overall efficiency. One effective method is to utilize advanced sensor technology that can provide real-time feedback on the robot's position and orientation. By integrating high-resolution encoders and laser positioning systems, operators can fine-tune the robot’s movements, ensuring that every weld is executed exactly as programmed. This data allows adjustments to be made dynamically, minimizing errors caused by external factors such as material variations or environmental conditions.

Another vital technique involves creating comprehensive training protocols using simulations and 3D modeling. By simulating various welding scenarios, trainers can visualize the robot’s movements and identify potential flaws in the programming before implementation. This preemptive approach helps in refining the robot's pathways and speeds, allowing for smoother and more accurate movements during actual welding tasks. Additionally, incorporating machine learning algorithms can further enhance the robot's ability to adapt and improve its performance over time by learning from past operations, which can lead to significant gains in precision and operational efficiency.

The integration of advanced programming techniques in robotics, particularly for welding applications, is essential for achieving optimal performance. According to a recent industry report by the International Federation of Robotics, the adoption of welding robots has increased by over 20% in the automotive sector alone, largely due to their ability to enhance precision and reduce cycle times. By leveraging sophisticated programming methods, manufacturers can tailor the capabilities of these robots to meet specific project demands, resulting in improved weld quality and consistency.

Advanced programming strategies, such as adaptive control algorithms and machine learning, enable welding robots to adjust in real-time to variables like material type and thickness. A study published in the Journal of Manufacturing Science and Engineering highlights that implementing adaptive control can increase welding accuracy by up to 30%, significantly diminishing the risk of defects and rework. Furthermore, with the advent of simulation software, operators can optimize robot trajectories and welding parameters before executing tasks on the production floor, leading to reduced downtime and enhanced throughput.

Collaboration between programming and welding technology is crucial in today’s manufacturing environment, where efficiency and precision are paramount. As the welding industry continues to evolve, embracing advanced programming techniques not only maximizes the capabilities of welding robots but also contributes to overall operational excellence. This holistic approach ensures that manufacturers remain competitive in a rapidly advancing market, making the most of their robotic investments.

When it comes to maximizing the efficiency and precision of welding robots, evaluating and maintaining their performance plays a crucial role in ensuring long-term success. Regular assessments can identify any performance discrepancies, allowing operators to recalibrate the systems and enhance their outputs. Investing time in training personnel to conduct thorough evaluations can minimize downtime and optimize production lines. Focus on key performance indicators (KPIs) such as cycle time, accuracy, and defect rates to measure the robots' operational efficiency.

Additionally, routine maintenance is essential for keeping welding robots in peak condition. Implementing a structured maintenance schedule that includes both preventive and corrective measures can significantly extend the lifespan of these machines. Pay particular attention to the robot’s joints and welding tools, ensuring they are regularly inspected and replaced as necessary. It’s advisable to establish a checklist for routine checks which should cover aspects like lubrication, connectivity, and calibration settings.

Tips for maintaining welding robots include keeping a detailed log of maintenance activities, allowing for easier analysis of trends and potential issues. Also, don’t overlook the importance of software updates and training for personnel to ensure they are up to speed with the latest programming techniques. By prioritizing these maintenance strategies, organizations can not only enhance the robots’ performance but also secure their investment for years to come.

| Metric | Description | Ideal Value | Current Value | Status |

|---|---|---|---|---|

| Cycle Time | Time taken to complete one welding cycle | 8 seconds | 10 seconds | Needs Improvement |

| Weld Quality | Percentage of acceptable welds | 98% | 95% | Satisfactory |

| Downtime | Total time machine is not operational | <1 hour/week | 2 hours/week | Needs Improvement |

| Energy Consumption | Energy used during operation | 50 kWh/week | 55 kWh/week | Satisfactory |

| Maintenance Intervals | Recommended time between maintenance | 500 hours | 600 hours | Satisfactory |