Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the rapidly evolving landscape of manufacturing and industrial processes, the adoption of automation technologies has become essential. One such advancement is the Flame Cutting Robot, which not only enhances precision in metal cutting operations but also significantly improves productivity and safety. According to a recent market analysis by Industrial Robotics Insights, the flame cutting robot market is expected to grow at a CAGR of 9.8% over the next five years, driven by increasing demand for high-quality automotive components and customized metal fabrication.

Experts emphasize the importance of integrating these advanced robotic solutions into modern operations. Dr. Emily Rogers, a leading authority in automation technologies, states, "The implementation of Flame Cutting Robots enables manufacturers to streamline their workflows and reduce operational costs, while maintaining superior cutting quality." This assertion highlights the dual benefits of efficiency and quality, making flame cutting robots an attractive investment for businesses looking to enhance their production capabilities.

As we explore the top ten Flame Cutting Robots to consider for your operations, it's crucial to understand how each model meets the diverse requirements of today’s manufacturing environments. From adaptability to various materials to user-friendly programming, the right flame cutting robot can be a game-changer in optimizing operational efficacy and addressing the unique challenges faced by industries today.

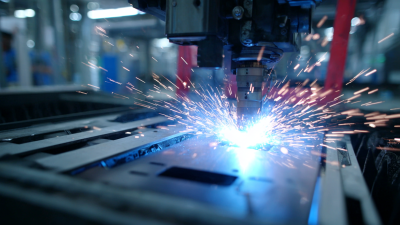

The evolution of flame cutting robots has significantly transformed industrial applications, marking a shift towards more efficient and precise manufacturing processes. As industries increasingly embrace automation, flame cutting robots have emerged as vital tools for metal fabrication. According to a recent report by the International Federation of Robotics, the global industrial robot market is set to reach $70 billion by 2025, driven largely by advancements in robotic technologies, including flame cutting. These robots enhance productivity by reducing the time required for cutting operations, with some systems boasting speeds up to 20 times faster than traditional cutting methods.

Additionally, the integration of advanced technologies such as artificial intelligence and machine learning has further refined the capabilities of flame cutting robots. A study conducted by the Robotics Industries Association highlights that automated cutting solutions are not only improving accuracy but also minimizing material wastage by up to 25%. As industries continue to seek sustainable practices, this efficiency becomes increasingly important. Moreover, the evolution of these robots has enabled them to adapt to complex cutting patterns and diverse materials, making them indispensable in sectors ranging from automotive to aerospace. The growing reliance on flame cutting robots symbolizes a broader trend towards the automation and digitization of manufacturing processes, paving the way for enhanced operational efficiency and innovation in the industry.

When selecting high-performance flame cutting robots for your operations, there are several key features that should be at the forefront of your decision-making process. First and foremost, precision is critical. A reliable flame cutting robot should offer exceptional accuracy in its cutting path, ensuring that the desired specifications are met without compromising material integrity. This precision can result in less material wastage and a smoother finish on the cut edges, ultimately enhancing the efficiency of the manufacturing process.

Another important aspect to consider is the robot's adaptability. A high-quality flame cutting robot should be versatile enough to handle different materials and thicknesses without requiring extensive modifications. Features such as adjustable flame intensity, automatic height adjustment, and the ability to work with various cutting gas combinations can significantly improve operational flexibility. Additionally, software compatibility that allows for easy integration with existing CAD/CAM systems can streamline workflow and enhance productivity. With these features in mind, you can equip your operations with a flame cutting solution that meets both current and future demands effectively.

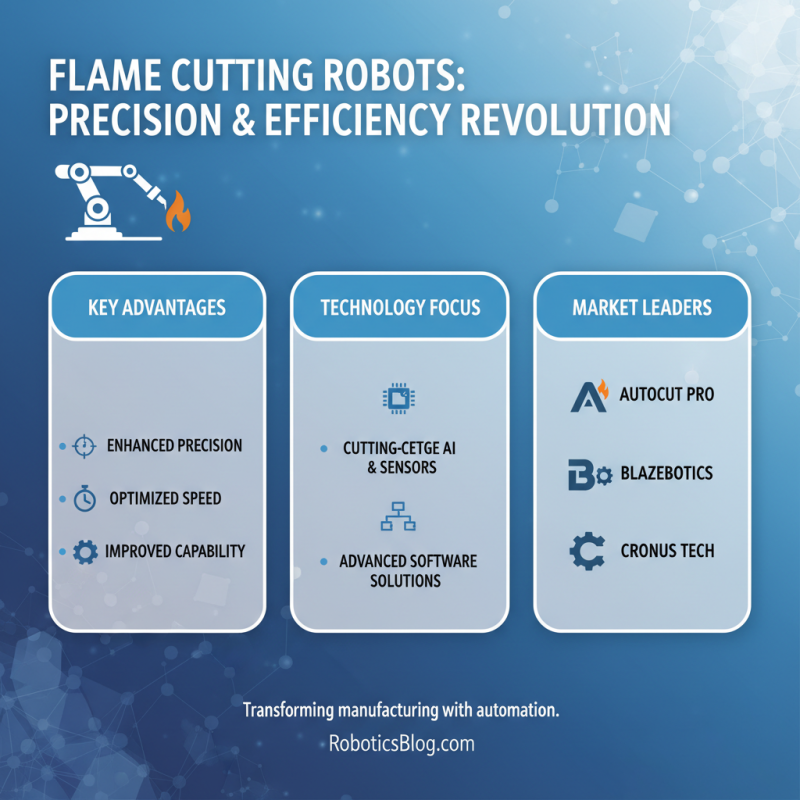

In the evolving landscape of automation and industrial technology, flame cutting robots have emerged as crucial tools for enhancing precision and efficiency in operations. Leading brands in the market are at the forefront of innovation, continuously developing advanced solutions that cater to diverse manufacturing needs. These brands leverage cutting-edge technology to create robots that not only improve cutting accuracy but also optimize production speed, ensuring that businesses can meet growing demands with enhanced capability.

The competitive flame cutting robot market is characterized by companies that prioritize research and development. Many of these industry leaders are integrating artificial intelligence and machine learning into their robotic systems, allowing for adaptive performance and real-time decision-making. This evolution is paving the way for smarter, more versatile machinery that can operate effectively in dynamic environments. As these brands establish their presence, they set new standards for quality and efficiency in flame cutting operations, making them essential partners for manufacturers looking to stay ahead in a fast-paced market.

In the realm of industrial fabrication, the choice between manual cutting and robotic flame cutting presents significant implications for efficiency and overall productivity. Manual cutting, while versatile and adaptable for smaller tasks, often suffers from inconsistencies in quality and speed. Workers may experience fatigue, leading to decreased precision over extended periods. Moreover, the reliance on human operators can result in longer lead times and increased production bottlenecks, particularly in high-demand environments.

On the other hand, flame cutting robots excel in delivering consistent, high-quality cuts with remarkable speed. These machines, programmed with advanced algorithms, can perform repetitive tasks with precision that is difficult for human operators to match. By minimizing human error and optimizing workflow, flame cutting robots not only enhance productivity but also reduce material waste. Furthermore, their ability to operate continuously without breaks translates to higher output rates, making them an appealing option for factories looking to streamline operations and meet tight deadlines efficiently. The comparative analysis clearly indicates that while manual techniques have their place, the advantages of incorporating flame-cutting robots are becoming increasingly compelling in modern manufacturing settings.

The integration of flame cutting robots into industrial operations has led to remarkable enhancements in both efficiency and precision. One of the most compelling success stories comes from the automotive manufacturing sector, where a facility adopted a flame cutting robot to streamline its metal processing. Initially facing challenges with manual cutting methods that resulted in significant material waste, the introduction of automation created a dramatic transformation. The robot not only improved cutting accuracy, reducing wastage by nearly 30%, but also enabled faster turnaround times, allowing the facility to meet growing production demands without compromising quality.

In another case, a steel service center sought to enhance its operational capabilities through robotic integration. By implementing a flame cutting robot, the center expanded its capacity to handle complex cuts that were previously time-intensive when performed manually. The robotic system provided consistent and repeatable results, minimizing the need for rework.

As a result, the service center reported a 25% increase in productivity, significantly boosting its competitive edge in the market. These success stories illustrate the transformative impact of flame cutting robots, highlighting their ability to optimize processes and foster growth in various manufacturing environments.