0102030405

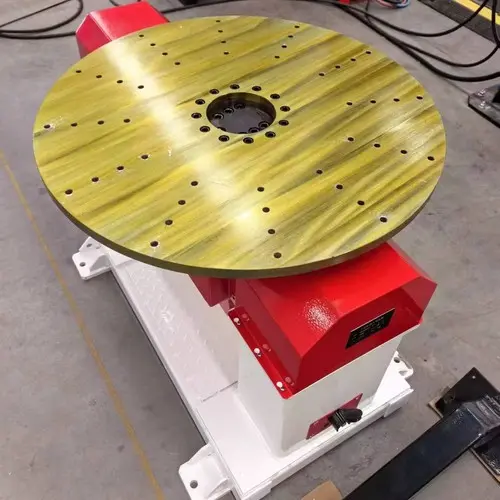

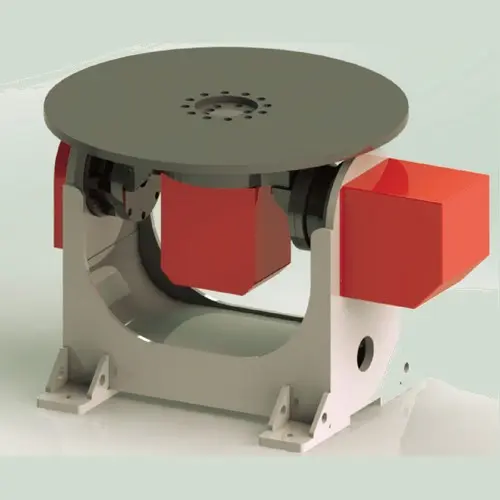

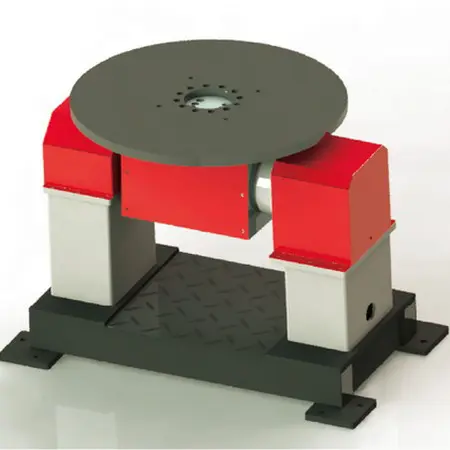

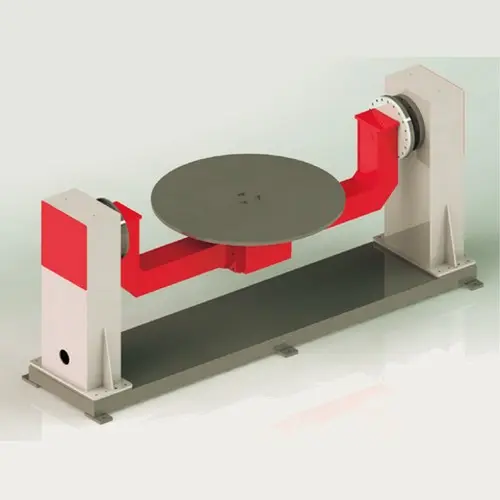

Dual-Axis U-Type Positioner

Product Introduction

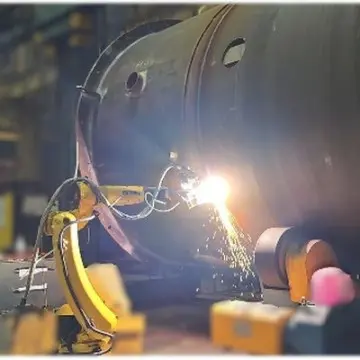

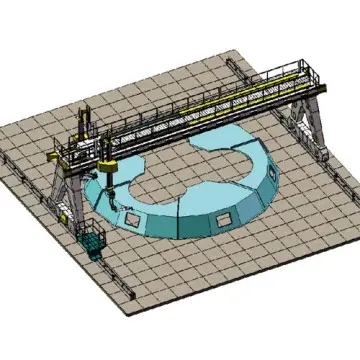

The Dual-Axis U-Type Positioner redefines precision positioning for advanced manufacturing, offering simultaneous two-axis rotation (horizontal and vertical) to handle intricate welding, machining, and assembly tasks. Featuring a robust U-shaped frame, this positioner securely clamps large or irregularly shaped workpieces—from mining equipment components to structural beams—enabling 360° horizontal rotation and ±180° vertical tilting for optimal accessibility.

Engineered for heavy industries such as mining machinery, energy infrastructure, and shipbuilding, this system ensures seamless integration with robotic welding cells, CNC machines, and automated production lines. Its modular design supports customization for load capacities up to 500 kg, making it ideal for oversized components like crusher housings, conveyor frames, and hydraulic cylinders.

Key Features

Dual-Axis Precision Control

Independent Axis Movement: Programmable horizontal (0.1–1.5 RPM) and vertical (0.05–0.8 RPM) rotation with ±0.05° accuracy.

Synchronized Motion: Perfectly aligned angles for complex weld joints (e.g., spiral seams, 3D contours).

Heavy-Duty U-Frame Design

Reinforced steel construction with anti-deformation rigidity for extreme loads (up to 50T).

Adjustable clamping arms with hydraulic/pneumatic fixtures to secure irregular geometries.

Smart Automation Integration

IoT-Ready: Compatible with PLC, CNC, or robotic controllers for real-time data exchange.

Pre-programmed motion profiles for repeatable workflows (e.g., batch processing of mining buckets).

Enhanced Safety & Durability

Overload sensors, emergency brakes, and anti-collision algorithms.

IP65-rated protection against dust, moisture, and welding spatter.

Energy Efficiency

Regenerative drive systems reduce power consumption by 25% during idle periods.

Why Choose Our U-Type Positioner?

Unmatched Flexibility: Tackle complex geometries with dual-axis maneuverability.

Built for Harsh Environments: Corrosion-resistant coatings and sealed components.

Coating/Spraying: Consistent surface treatment for corrosion protection.

Global Service Network: On-site installation support and 24/7 troubleshooting.

Technical Parameters

| Model | Capacity (kg) | Disc Diameter (mm) |

| WELD-4030P-050 | 300 | Ø500*23H |

| WELD-4050P-050 | 500 | Ø500*23H |

| WELD-4030P-080 | 300 | Ø800*28H |

| WELD-4050P-080 | 500 | Ø800*28H |

| WELD-4030U-050 | 300 | Ø500*23H |

| WELD-4050U-050 | 500 | Ø500*23H |

| WELD-4100U-080 | 1000 | Ø800*28H |

description2