0102030405

Single-Axis Horizontal Turning Positioner

Product Introduction

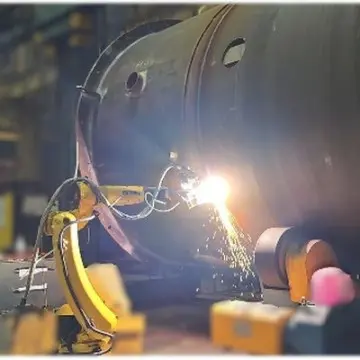

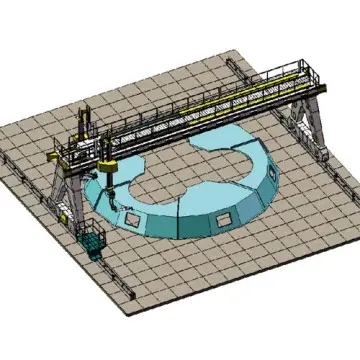

The Single-Axis Horizontal Turning Positioner is a robust, high-performance rotary positioning device engineered to streamline welding, assembly, and inspection processes. Designed for heavy-duty industrial applications, this equipment enables 360° horizontal rotation of workpieces, ensuring optimal positioning accuracy and stability. Ideal for cylindrical, symmetrical, or irregularly shaped components, it simplifies complex welding tasks while reducing operator fatigue and production downtime.

Widely used in automotive manufacturing, aerospace, heavy machinery, and pipeline fabrication, our positioner is compatible with robotic welding systems, manual welding torches, and automated production lines. Its modular design supports customization to meet diverse load capacities, workpiece dimensions, and operational environments.

Key Features

1.High Load Capacity & Durability

Supports 50 kg to 2000 kg workpieces (customizable).

Reinforced steel frame and precision bearings ensure longevity under extreme loads.

2.Precise Motion Control

Variable Speed Adjustment: 0.1–2.0 RPM for smooth, controlled rotation.

±0.1° Positioning Accuracy: Achieved via servo motors or gear-driven mechanisms.

3.User-Friendly Operation

Intuitive PLC or HMI interface for programmable rotation cycles.

Emergency stop, overload protection, and anti-slip clamps for enhanced safety.

4.Versatile Compatibility

Integrates seamlessly with robotic arms, welding power sources, and IoT platforms.

Adaptable mounting options: T-slots, bolt holes, or custom fixtures.

5.Low Maintenance Design

Dustproof and splash-resistant construction (IP54 standard).

Self-lubricating components reduce wear and operational costs.

Applications

Welding: Uniform rotation for circumferential welds on pipes, tanks, and shafts.

Assembly: Precise alignment of gears, flanges, and structural components.

Coating/Spraying: Consistent surface treatment for corrosion protection.

Inspection: 360° access for non-destructive testing (NDT) and quality checks.

Technical Parameters

| Model | Capacity (kg) | Disc Diameter (mm) |

| WELD-4030D-080 | 300 | Ø800*23H |

| WELD-4050D-080 | 500 | Ø800*23H |

| WELD-4100D-120 | 1000 | Ø1200*28H |

| WELD-4200D-120 | 2000 | Ø1200*38H |

description2