0102030405

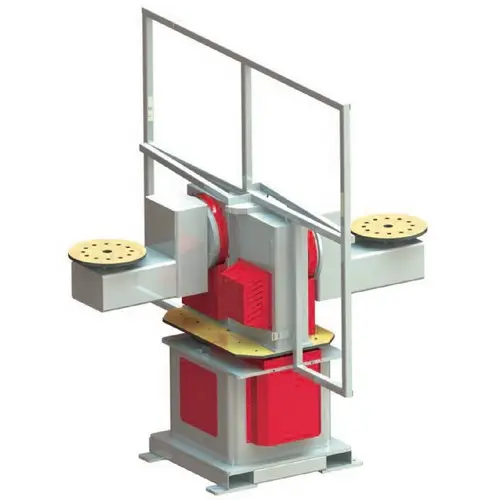

WWELD Custom Welding Robot Positioner

Product Introduction

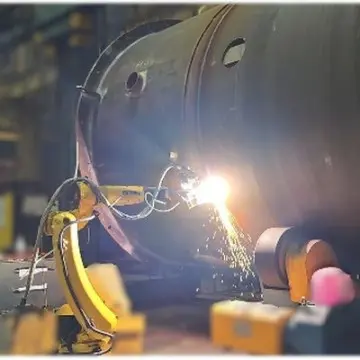

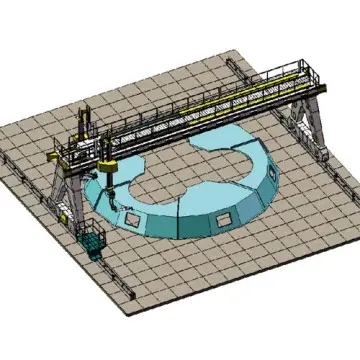

The Custom Welding Robot Positioner is a cutting-edge automation solution designed to optimize robotic welding workflows across industries. Engineered for seamless integration with industrial robots, this positioner offers multi-axis motion control (2–6 axes) to rotate, tilt, or flip workpieces with sub-millimeter accuracy, ensuring consistent weld quality and eliminating manual repositioning. Ideal for high-mix, low-volume production or complex geometries—from aerospace components to automotive chassis—our customizable systems adapt to your unique manufacturing challenges.

Built for automotive, shipbuilding, energy, and general fabrication, this positioner supports collaborative robots (cobots), articulated robots, and welding cells. Its modular architecture allows tailored configurations for load capacities, rotation speeds, and control interfaces, empowering you to achieve faster cycle times, reduced scrap rates, and 24/7 productivity.

Key Features

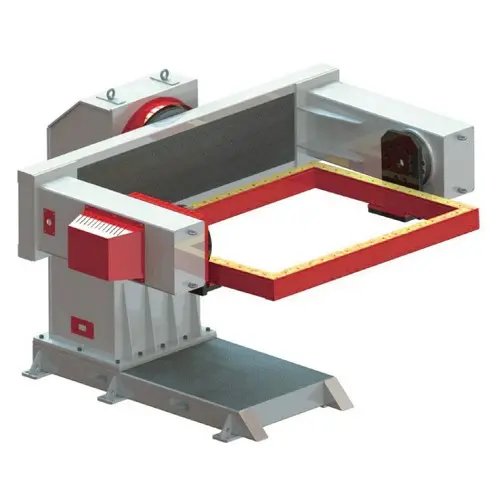

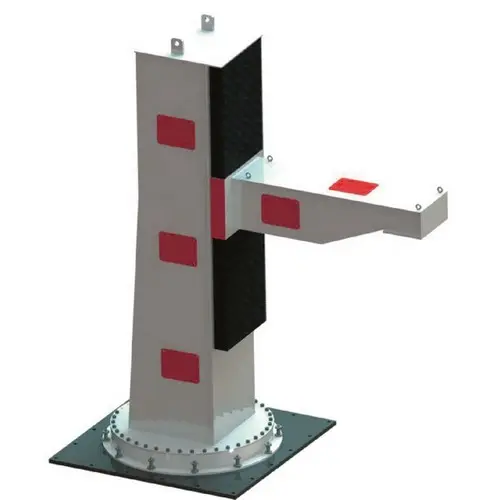

Fully Customizable Design

Axis Configuration: 2–6 axes (rotation, tilt, lift, etc.) to match robot reach and weld angles.

Payload Adaptability: Custom fixtures, clamps, and turntables for irregular or oversized parts.

Synchronized Robot Control

Real-Time Communication: Integrates with Fanuc, ABB, KUKA, or Yaskawa controllers via EtherCAT/Profinet.

Path Planning Software: Pre-programmed motion paths for complex welds (e.g., 3D curves, circumferential seams).

Ultra-Precise Motion

Servo-Driven Accuracy: ±0.02° repeatability for laser-welding and micro-joining applications.

Variable Speed: 0.05–5.0 RPM with smooth acceleration/deceleration to prevent workpiece slippage.

Rugged & Smart Construction

Heavy-Duty Frame: High-strength steel or aluminum alloy with anti-vibration dampers.

IoT Connectivity: Monitor performance, predict maintenance, and optimize cycles via cloud platforms.

Safety & Compliance

Collision Detection: Force-torque sensors and emergency stop protocols.

Certifications: CE, ISO 10218, and ANSI/RIA R15.06 compliant.

Application

Automotive: Rotating car body panels for spot welding and laser brazing.

Aerospace: Tilting turbine blades for TIG welding in confined spaces.

Heavy Machinery: Flipping excavator booms for multi-pass submerged arc welding.

Renewable Energy: Positioning wind tower flanges for robotic MAG welding.

Why Choose Our Custom Positioner?

End-to-End Engineering Support: Co-design with our robotics experts for flawless integration.

Future-Proof Upgrades: Expand axes or upgrade software as production needs evolve.

Global Warranty: 1-year coverage with priority technical support.

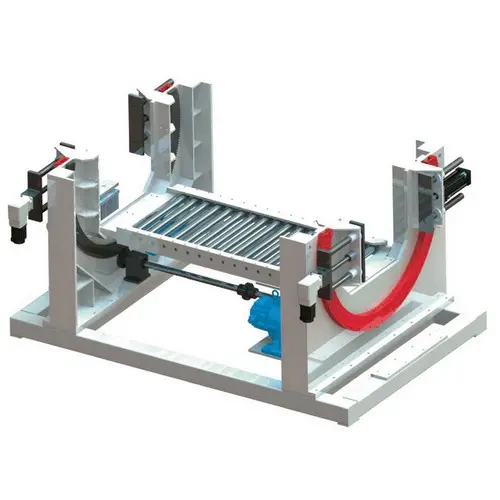

description2