Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

When planning your next fabrication project, consider the advantages of Automatic Welding Equipment. This technology revolutionizes how we approach welding tasks. It offers speed, precision, and consistency that manual techniques often can't match. Projects can be completed faster, with less rework required.

Automatic Welding Equipment reduces human error. It ensures uniform welds, minimizing the risk of weak joints. This is crucial for structural integrity in demanding applications. However, investing in such equipment requires careful consideration. Not every project may benefit equally from automation.

Some users find learning curves challenging. Training staff to operate automated systems can be time-consuming. It's vital to weigh these factors against the benefits. Automatic Welding Equipment can transform your project, but only if aligned with your specific needs.

Automatic welding equipment has become essential in modern manufacturing. It offers numerous advantages that traditional methods cannot match. One significant benefit is consistency. Automatic welding ensures uniform weld quality. This reduces the likelihood of defects, which can be costly to fix later.

Another key advantage is speed. Automated systems work faster than manual welding. This efficiency allows for quicker project completion. However, it also raises questions. Can workers adapt to this rapid pace? There may be a learning curve that requires time and training. Human oversight remains crucial in managing these machines.

Moreover, automatic welding reduces labor costs. Fewer workers are needed on-site, which can be cost-effective. Yet, this shift may lead to job displacement. Companies should consider the implications as they invest in technology. Balancing automation with the human workforce will be vital in the years to come.

| Advantage | Description | Impact on Production |

|---|---|---|

| Increased Efficiency | Automatic welding equipment can operate continuously, reducing cycle times and increasing output. | Higher production rates and faster project completion times. |

| Consistent Quality | Automated processes reduce human error, resulting in uniform weld quality. | Improved product reliability and reduced rework costs. |

| Cost-Effectiveness | Although initial investment is higher, long-term savings on labor and materials can be significant. | Lower overall project costs and improved profit margins. |

| Enhanced Safety | Reduced human exposure to hazardous welding processes minimizes accidents. | Safer working environments and lower insurance costs. |

| Flexibility | Modern automatic welding equipment can be programmed for multiple tasks, accommodating varying project needs. | Ability to handle diverse projects without extensive downtime. |

When considering automatic welding machines, several key features should guide your selection.

Speed is paramount. Faster machines can boost productivity, reducing project timelines.

However, balance this with the quality of welds. High speed may compromise strength.

Evaluate if speed aligns with your project needs.

Another essential feature is versatility.

Automatic welding equipment should adapt to various materials and thicknesses. Some machines struggle with different metals.

You may find that a single machine cannot handle all tasks. It’s wise to assess future projects before settling on an option.

User-friendliness also matters.

Intuitive controls make operation smoother but often require a learning curve.

Training might be necessary. This aspect can lead to downtime and impact project schedules.

Pay attention to reviews about ease of use. Can operators quickly grasp the machine’s functions?

The right choice can minimize headaches later.

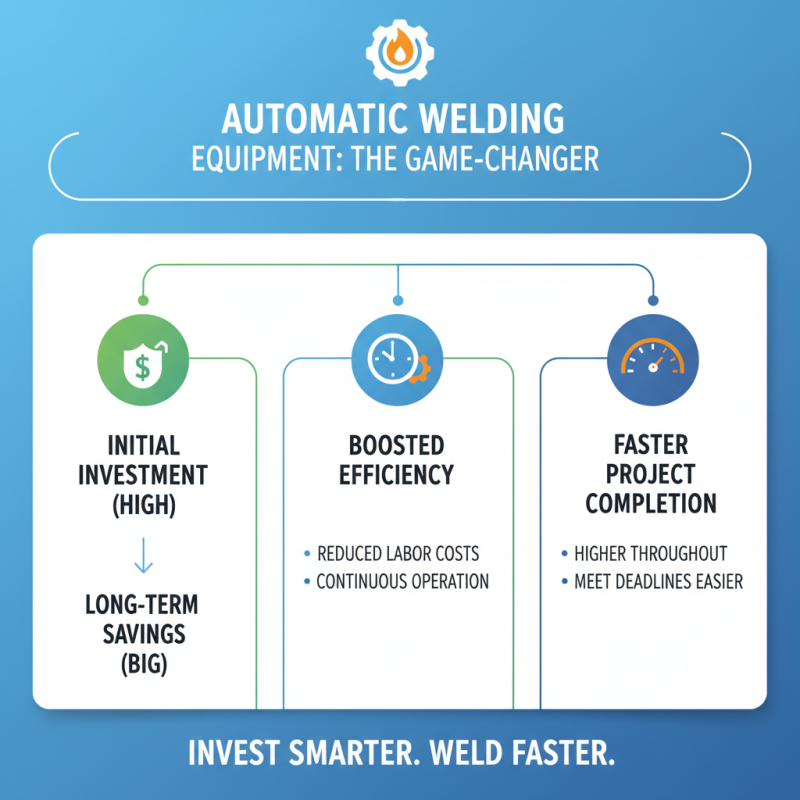

Investing in automatic welding equipment can be a game-changer for many projects. The initial cost may seem high, but the long-term savings are significant. Automatic machines boost efficiency by reducing labor costs. They can operate continuously, unlike manual labor which requires breaks. This leads to higher throughput and faster project completion.

However, it’s essential to evaluate your specific needs. Not all projects require high-end technology. Sometimes manual welding may be more suitable for small-scale or intricate tasks. It's vital to analyze the scale of production and welding complexity. You may find that automatic welding isn't always the best fit, leading to overspending.

Additionally, training staff to operate new equipment can create an added expense. Misunderstandings about how machines work could lead to initial losses. Moreover, the technology can become outdated quickly. Investing in automatic welding is not just about immediate benefits. It requires ongoing assessments of needs, costs, and potential updates. Automation promises significant advantages, but careful consideration is essential.

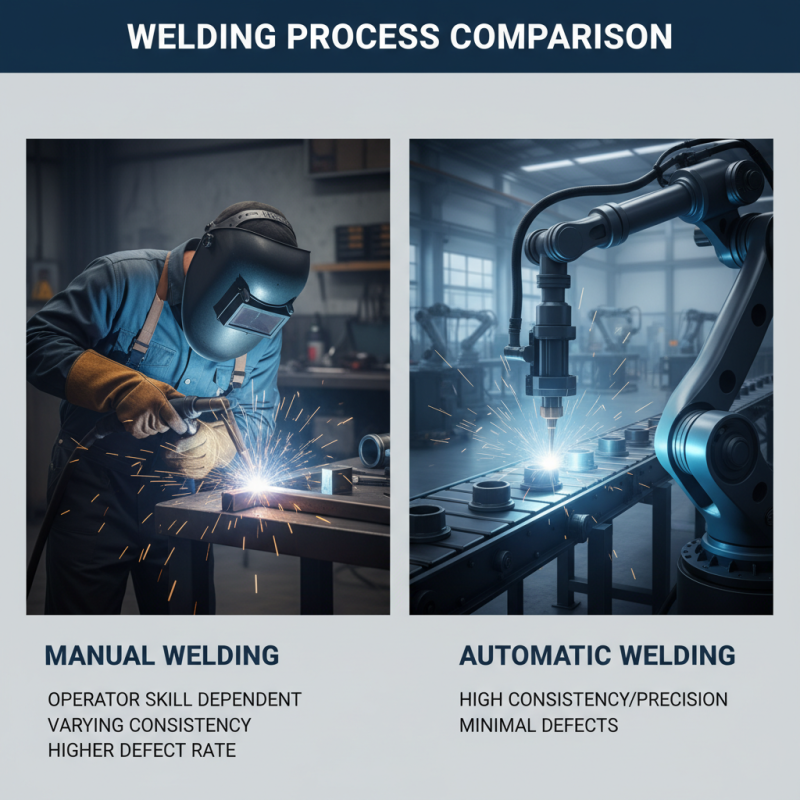

When considering welding processes, the automatic method stands out for various reasons. Unlike manual welding, where the operator's skills directly influence the result, automatic welding relies on technology. This leads to increased consistency and precision in repeated tasks. Automatic machines often produce a cleaner weld, minimizing defects. They can enhance the quality of the final product, especially in high-volume projects. However, they aren't without their challenges.

Manual welding allows for flexibility and adaptation on the spot. Skilled welders can navigate complex joints or unexpected issues. They can alter their techniques based on real-time feedback, which machines may struggle to do. This makes manual welding ideal for unique projects or intricate designs. Nonetheless, training a proficient welder takes time and resources. The cost of errors can be high, especially in critical applications.

Both methods have their merits and limitations. Automatic welding can significantly speed up production while manual welding offers adaptability. However, the right choice often hinges on project requirements and available resources. Each project benefits from careful consideration of these factors to achieve the best outcome.

In recent years, automatic welding equipment has evolved rapidly. Future trends indicate a shift towards smarter machines. These machines will integrate artificial intelligence for improved precision. They're designed to learn from each weld they perform. This adaptability could reduce waste and enhance efficiency.

When planning your next project, consider these tips: assess the project scale, and choose equipment that matches your needs. Focus on user-friendly interfaces. A complicated setup can lead to errors. Efficiency matters, but so does ease of use.

Another emerging trend is enhanced safety features. Expect automatic shut-offs and advanced monitoring systems. These innovations help protect operators from injuries. However, don’t overlook the importance of training. Operators should fully understand the equipment's capabilities and limitations. Relying solely on technology without skill can lead to imperfect outcomes.

This chart illustrates the adoption rates of various automatic welding techniques in 2023. Robotic welding leads with a 35% adoption rate, followed by laser welding at 25%. Traditional methods like TIG and MIG welding are still relevant but less adopted compared to newer technologies.